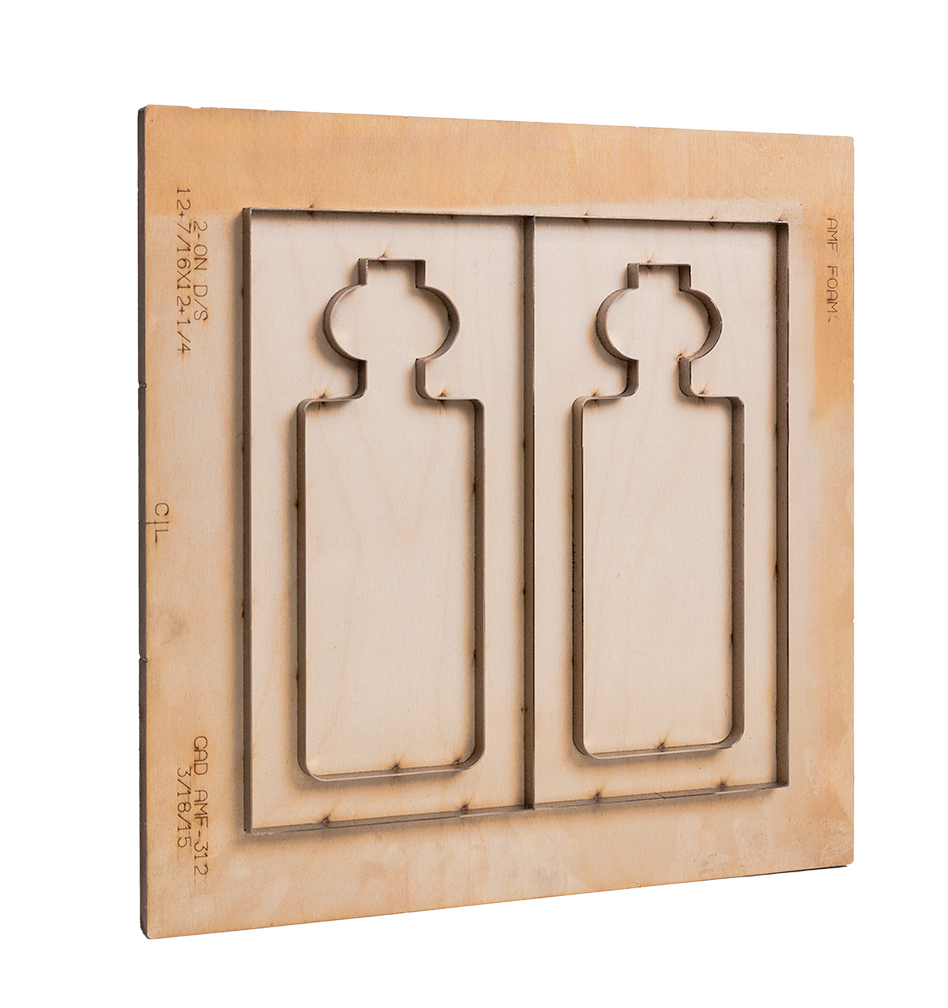

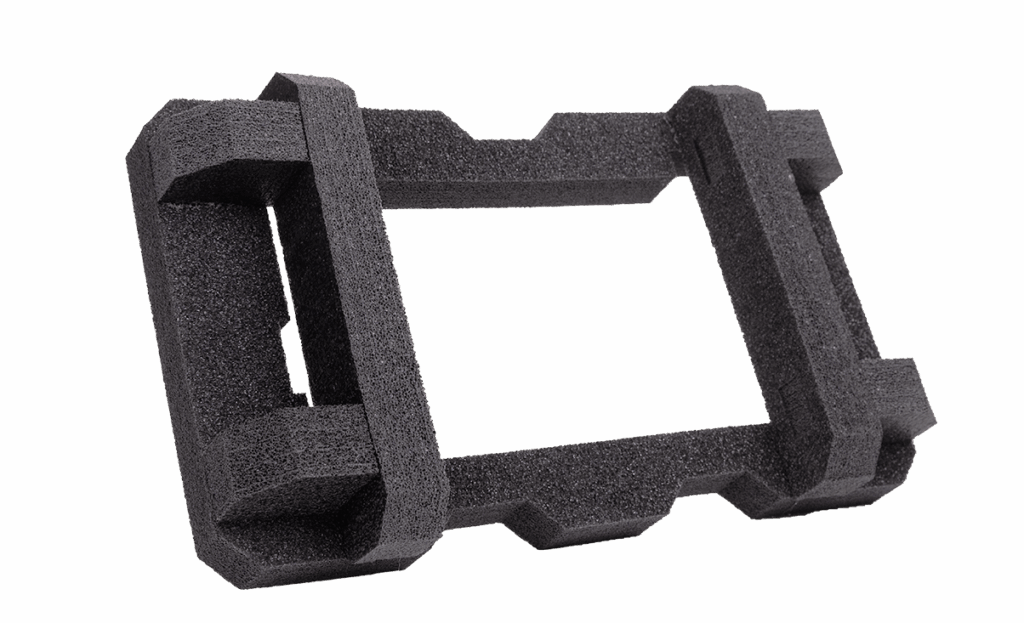

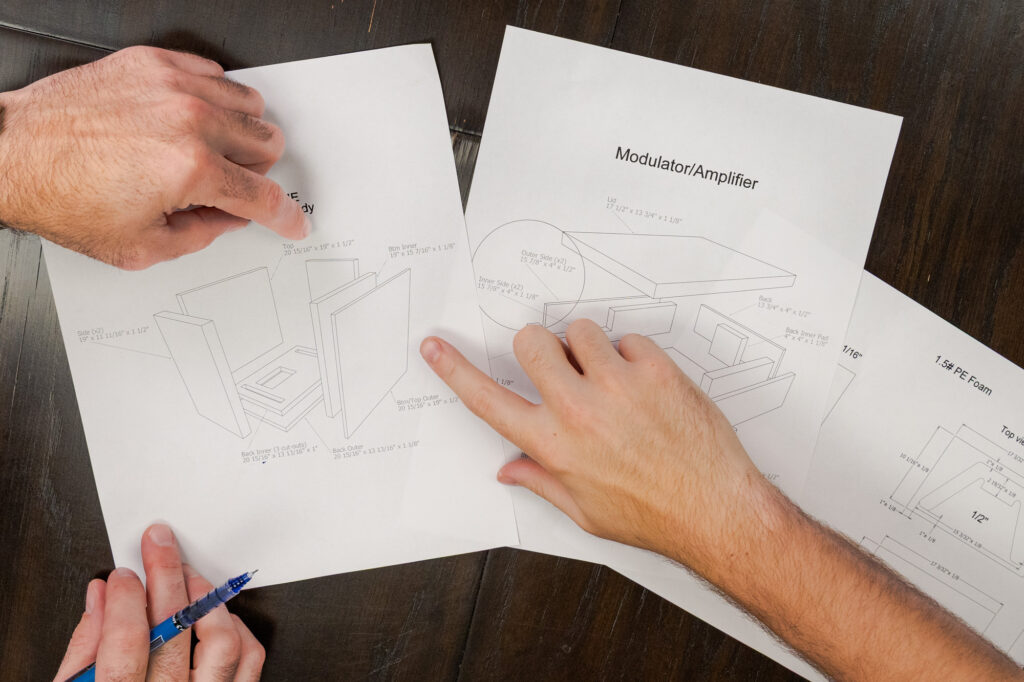

Absolutely. At AM Foam Products, we understand the importance of seeing and testing a product before committing to a full production run. We offer custom die cut prototypes, so you can evaluate the design, fit, and function in real-world conditions. This process helps us identify any necessary adjustments early, ensuring the final parts meet your performance standards and reducing the risk of costly revisions.

Custom Die Cutting Services You Can Rely On

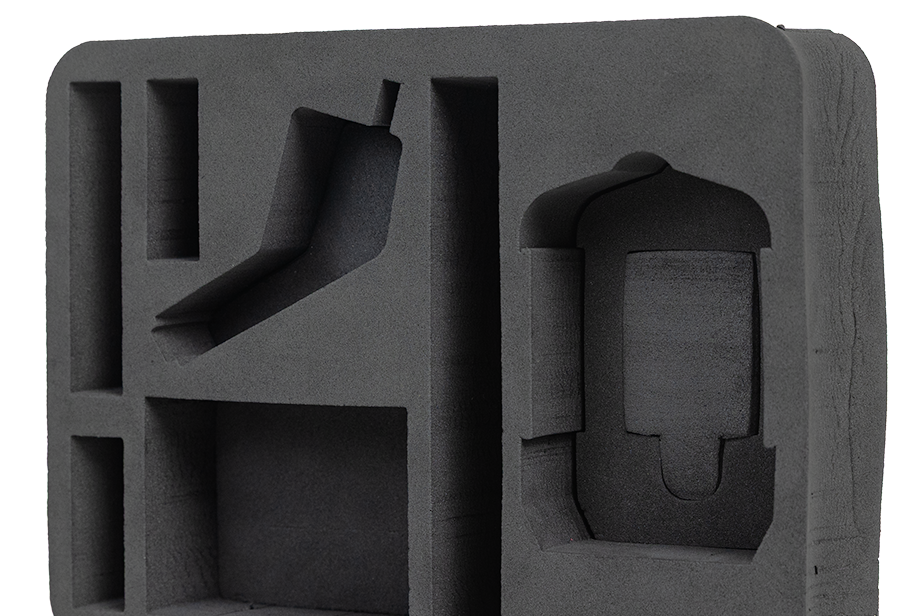

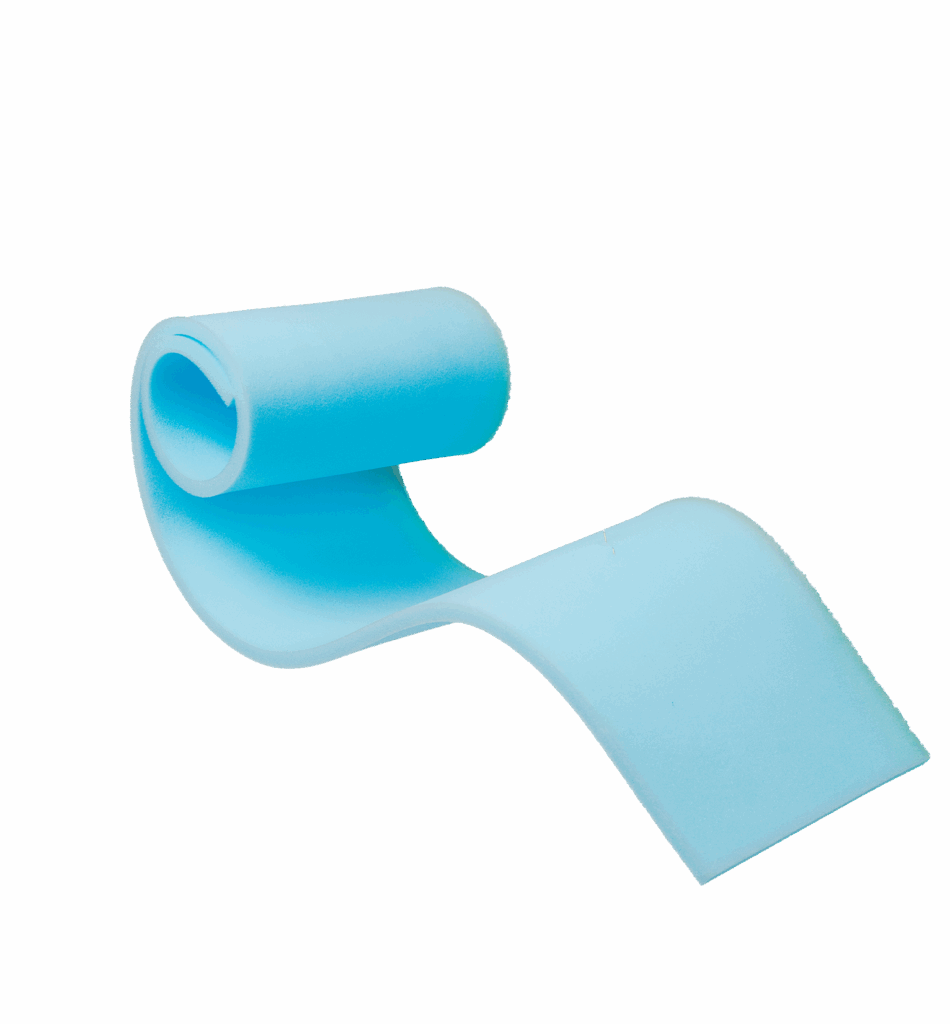

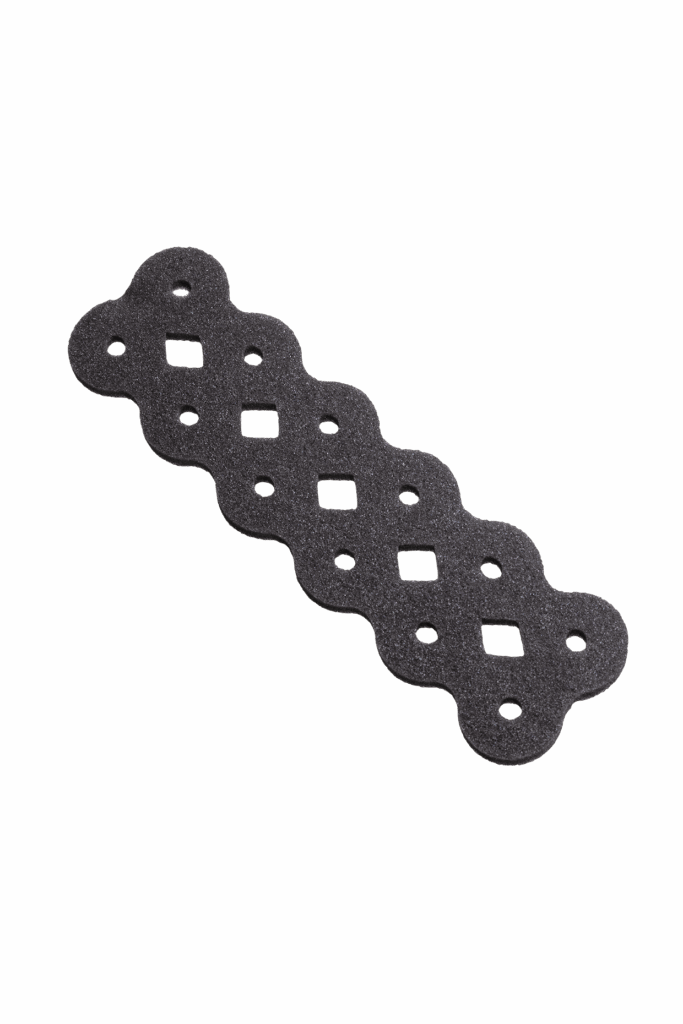

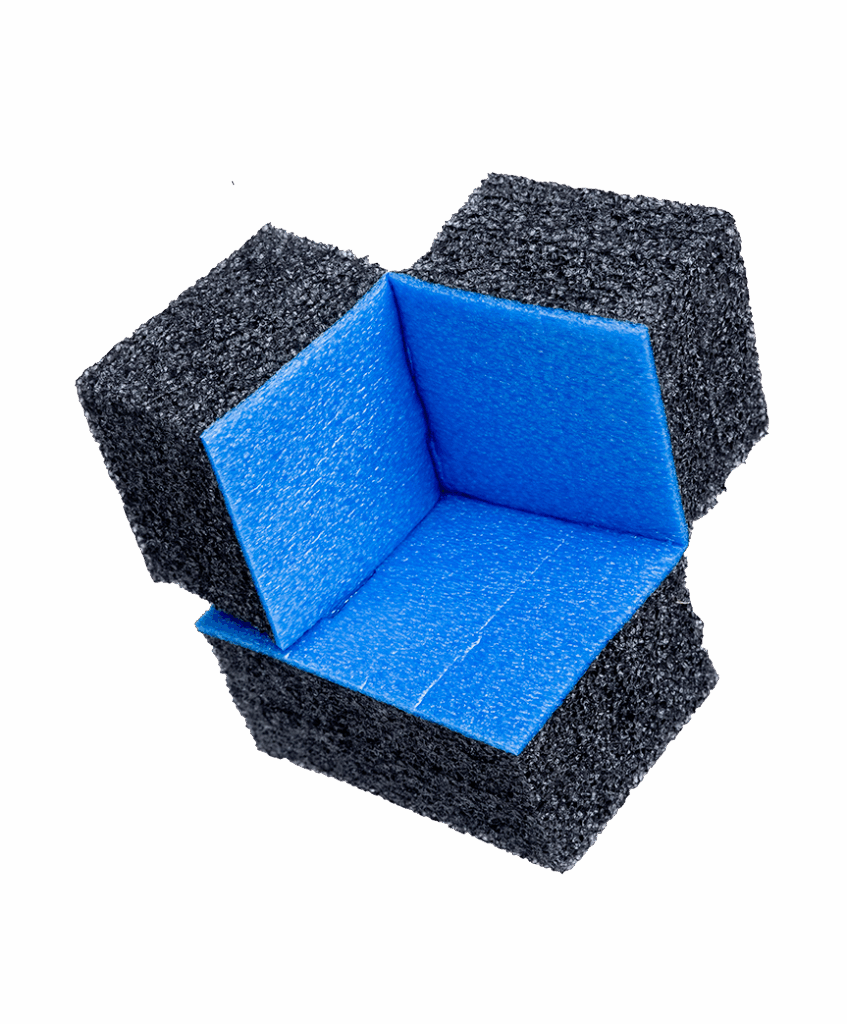

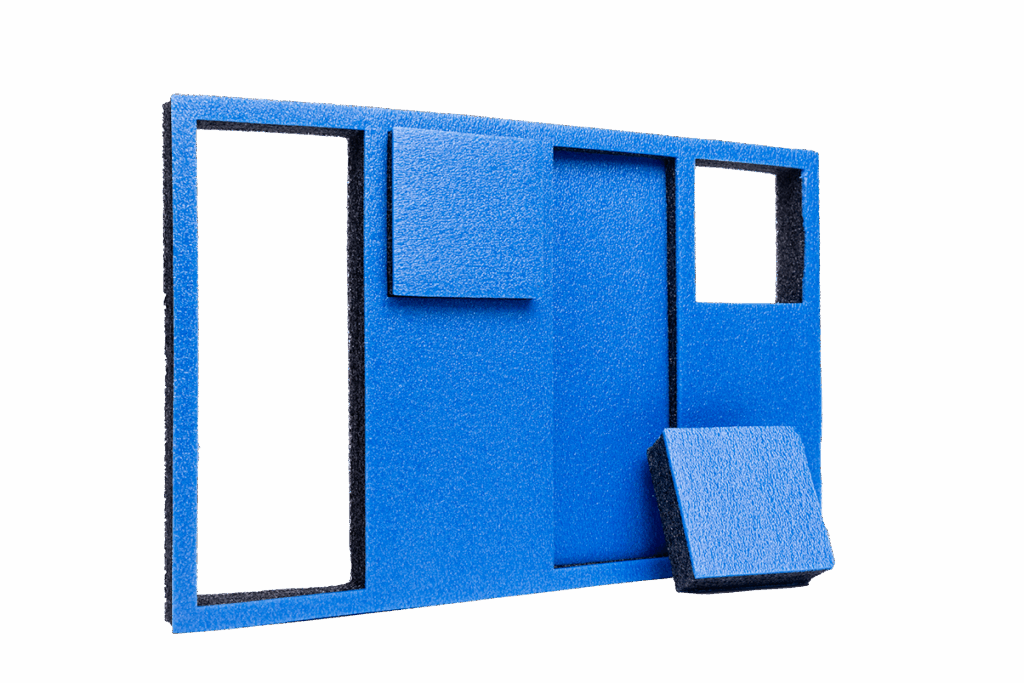

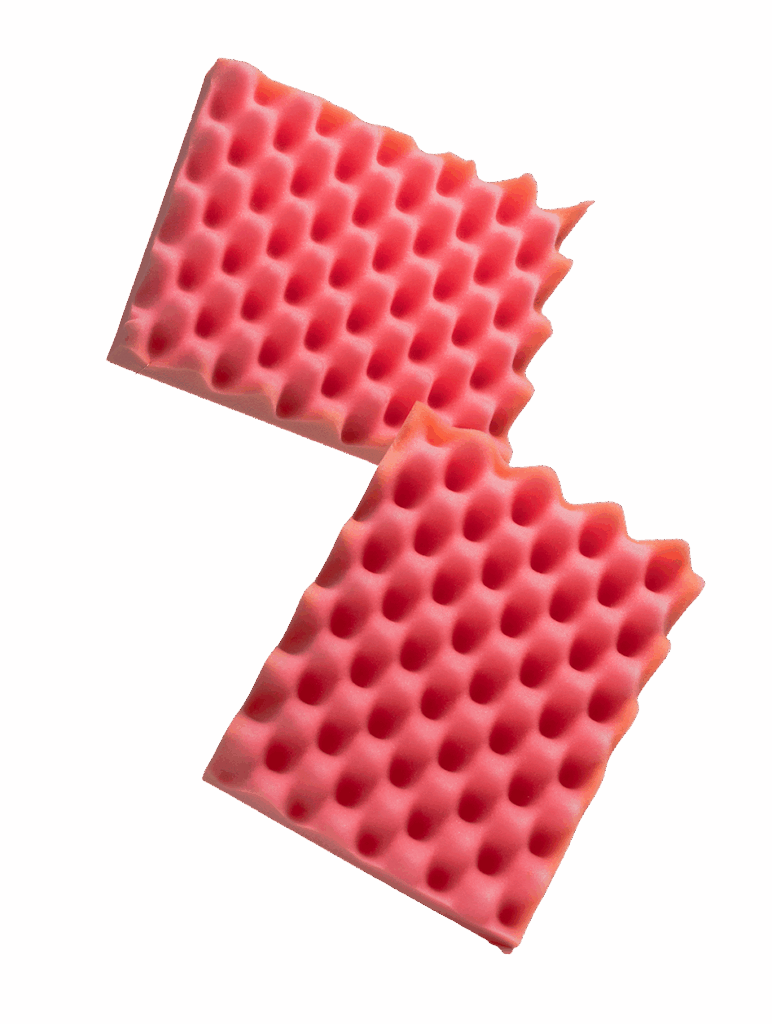

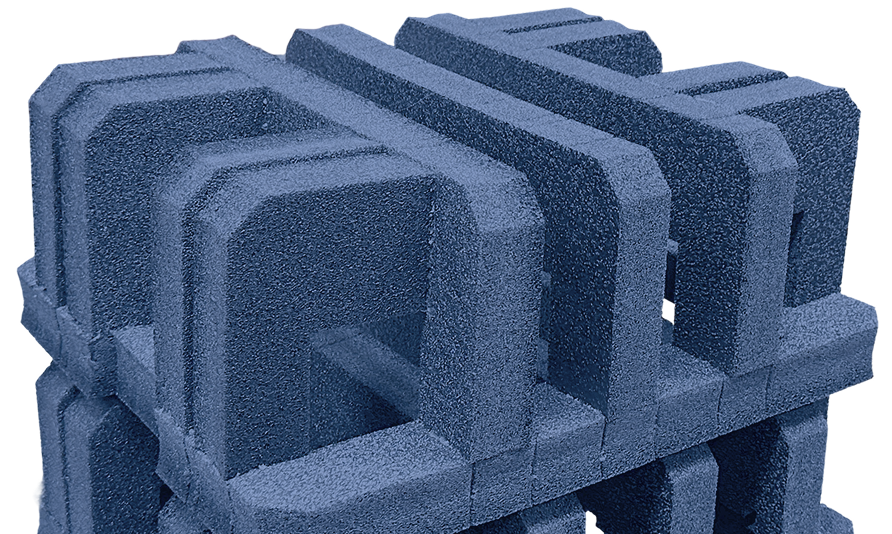

At AM Foam, we offer custom die cutting services for precise, repeatable parts across industries, from aerospace parts to retail packaging, with unmatched quality and turnaround. Whether you need one prototype or thousands of identical parts, our die cutting capabilities deliver exact results every time. We work with foam, rubber, and specialty materials, providing parts that fit perfectly and perform reliably.

Die Cutting Solutions for Any Application

From simple shapes to intricate designs, we have the expertise and equipment to handle your die cutting project quickly and accurately.

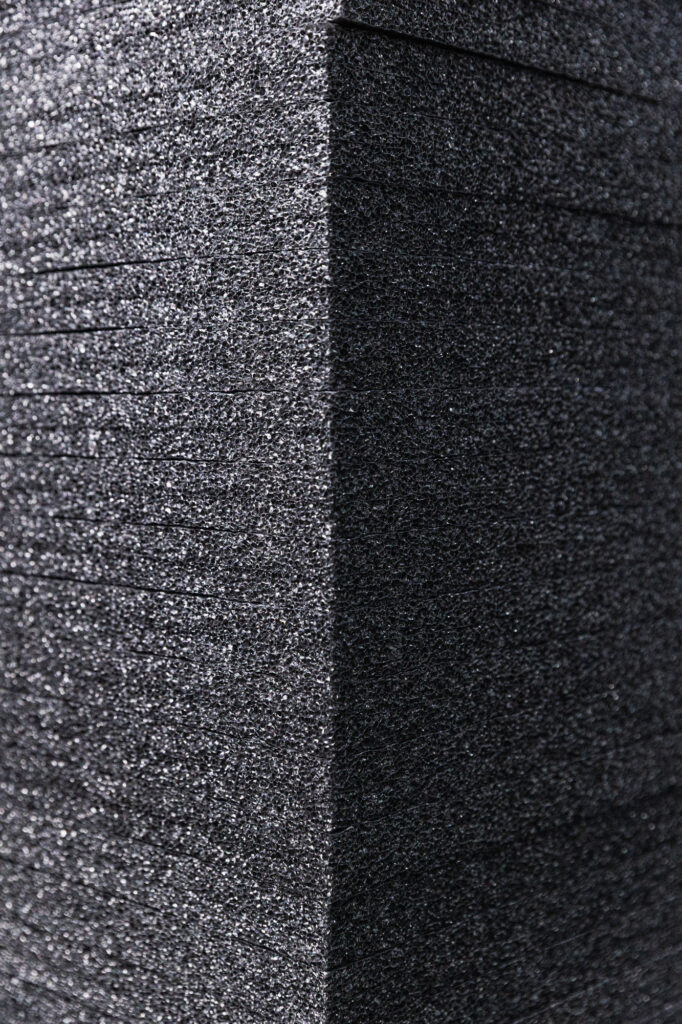

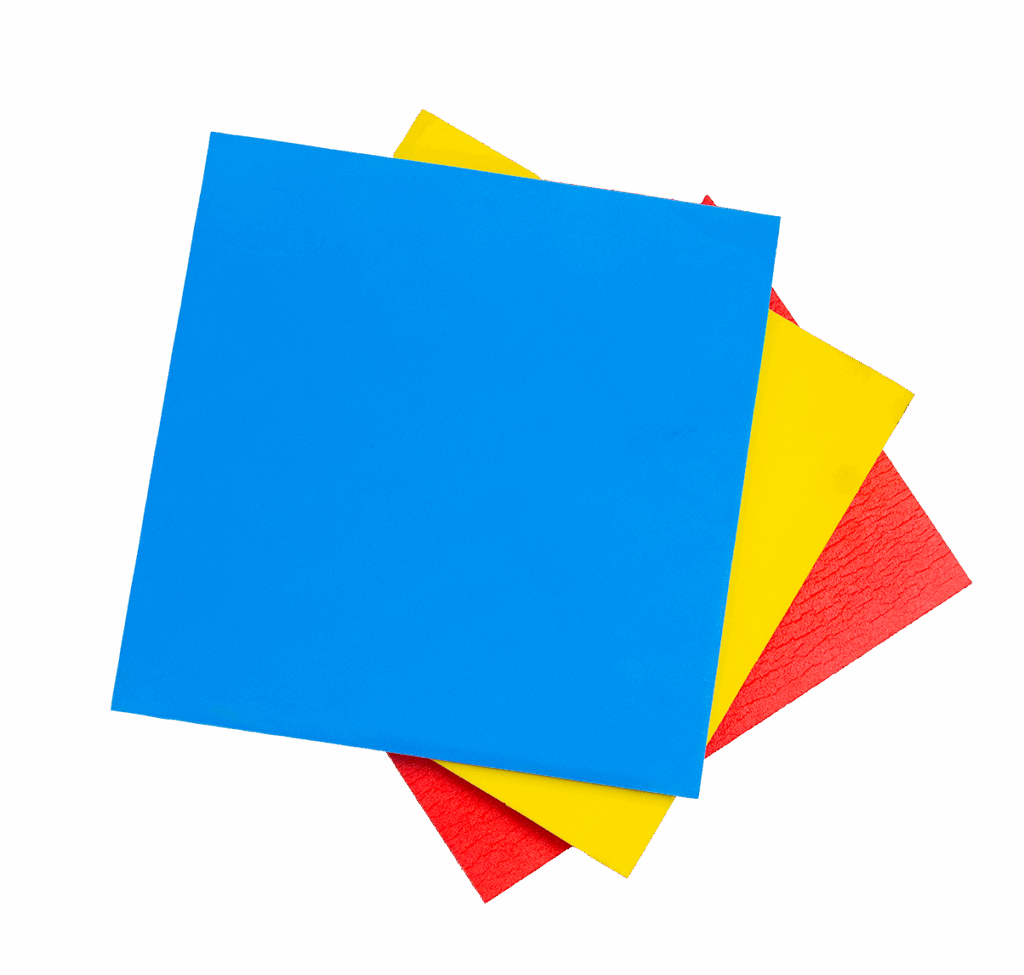

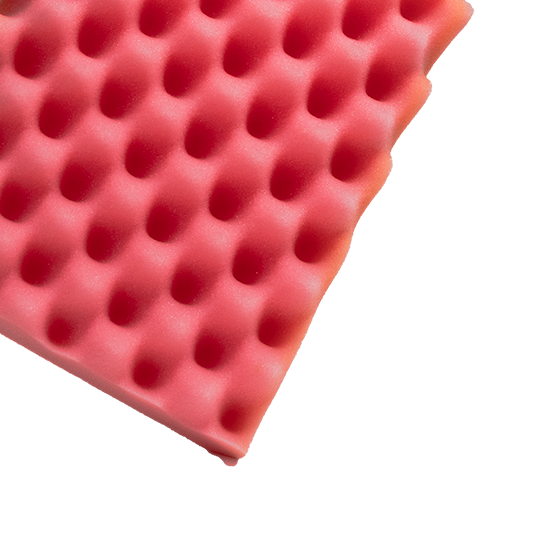

Zoom In On Our Materials

Not Sure What Foam Product Fits Best?

Let our tool help you choose the right solution for your application.

Check Out Our Process

Let’s Build Your

Custom Designed Solution

Die Cutting Done Right, From Prototype to Production

With state-of-the-art equipment and decades of experience, we have the ability to die cut almost any design—from large-scale components to small, intricate parts—while maintaining exceptional accuracy and consistency.

Not Sure Yet? These FAQs Might Help

Turnaround time varies depending on factors like part complexity, order volume, and material availability. However, our streamlined, in-house workflows and advanced equipment—such as large 4-post presses and precision clicker presses—allow us to complete many die cutting jobs faster than industry averages. Whether you need a short-run order or a high-volume production, we work to meet your deadlines without sacrificing quality.

Yes. We can work directly from CAD files, technical drawings, or even physical samples to produce accurate die cut parts that match your specifications. Our engineering team reviews all files for compatibility with our die cutting processes, ensuring precise, consistent results across your entire order. If needed, we can also assist with file adjustments or suggest materials to enhance performance and reduce waste.