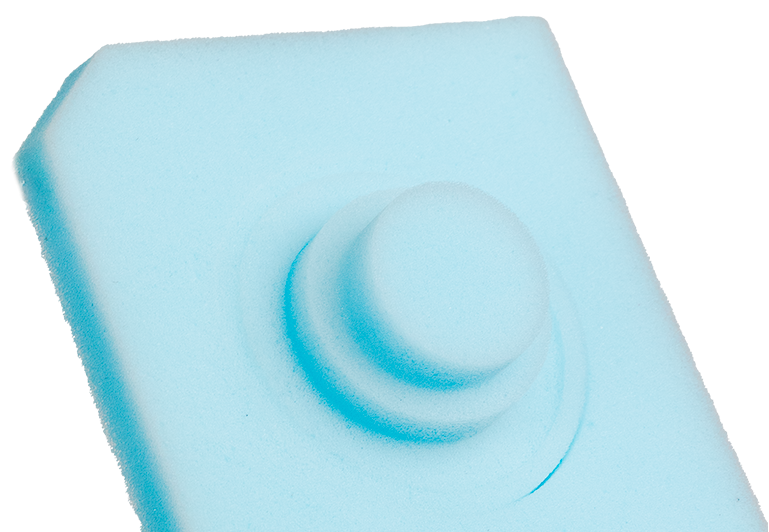

We provide a wide selection of medical-grade foams, including polyurethane, polyethylene, and cross-linked foams, each tailored to meet the rigorous demands of healthcare applications. Polyurethane foams offer exceptional cushioning and flexibility, making them ideal for wound care dressings, surgical padding, and patient positioning products. Polyethylene foams are lightweight, durable, and resistant to moisture, making them perfect for medical packaging and orthopedic supports. Cross-linked foams deliver superior strength, chemical resistance, and a smooth, nonporous surface—excellent for applications requiring easy cleaning and repeated use.

Durable Foam for Medical Applications

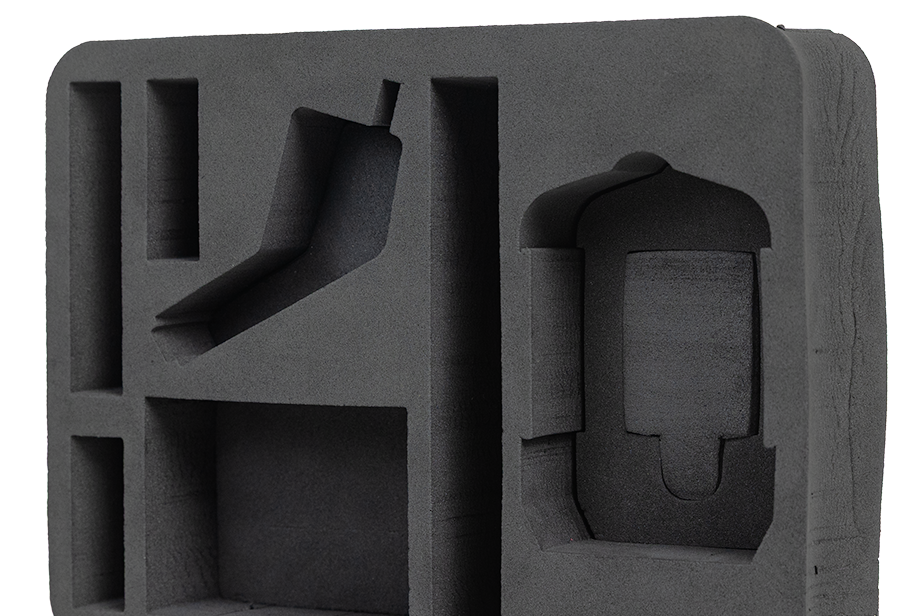

At AM Foam Products, we understand that healthcare applications demand exceptional precision and safety. Our medical-grade foam solutions are engineered to protect sensitive instruments. From surgical equipment packaging to specialty device cushioning, our high-quality solutions safeguard the products that save lives.

Custom Foam Shapes From Packaging to Patient Comfort

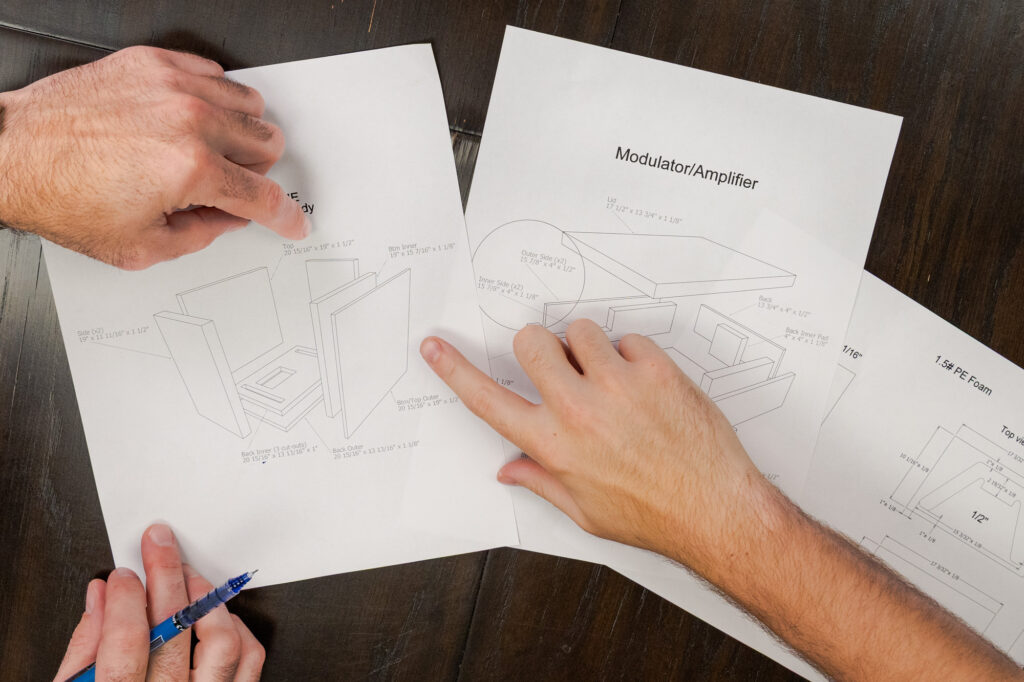

We can work from CAD files or prototype samples to create custom-designed solutions at your product’s specific dimensions and protection requirements.

Let’s Build Your

Custom Foam Solution

Check Out Our Process

High-Performance Foam for Medical Devices & Equipment

At AM Foam Products, we specialize in providing medical-grade foam solutions engineered to meet the demanding standards of healthcare packaging. Whether you’re protecting sensitive surgical instruments, cushioning diagnostic devices, or require custom foam components for patient care, our products deliver the reliability your industry requires.

Not Sure Yet? These FAQs Might Help

Absolutely. AM Foam Products’ manufacturing capabilities are designed to support projects of any scale—from small prototype batches to full-scale, high-volume production. Our team works closely with you to refine designs, meet strict standards, and maintain consistent performance across every batch. No matter your business size, you can rely on our flexible production schedules and precise quality control processes to meet deadlines and budgets.

Yes. Many of our medical-grade foams are specifically engineered for compatibility with standard sterilization methods, including autoclaving, gamma irradiation, and ethylene oxide (EtO) sterilization. We understand the importance of maintaining material integrity and performance during sterilization. Our team can guide you toward the right foam for your specific application. By matching your product’s needs with the appropriate material, we ensure your components remain safe, reliable, and compliant with healthcare standards.