We work with a broad range of rubber materials to meet different performance needs. This includes EPDM for weather and ozone resistance, neoprene for chemical and oil resistance, nitrile for fuel and solvent applications, silicone for high-temperature flexibility, and natural rubber for general elasticity. Each material has unique properties. We help you match the right type to your specific application so your parts perform exactly as intended.

Expert Rubber Fabrication for Small or Large Runs

At AM Foam Products, we make custom sponge rubber fabrication easy and reliable. Gaskets, seals, padding, or protective components; no matter the purpose, we can create rubber products that fit your project. We work with a variety of rubber materials to deliver durable, high-quality parts for industrial, commercial, and specialty applications.

Shaped, Cut, and Fit Your Way

At AM Foam Products, we specialize in custom sponge rubber fabrication using a variety of high-quality materials. Whether you need industrial-grade durability, outdoor weather resistance, or specialized performance properties, our team can create the product you need down to your exact specs.

Let’s Build Your

Custom Rubber Solution

Check Out Our Process

All the Rubber Options You Need

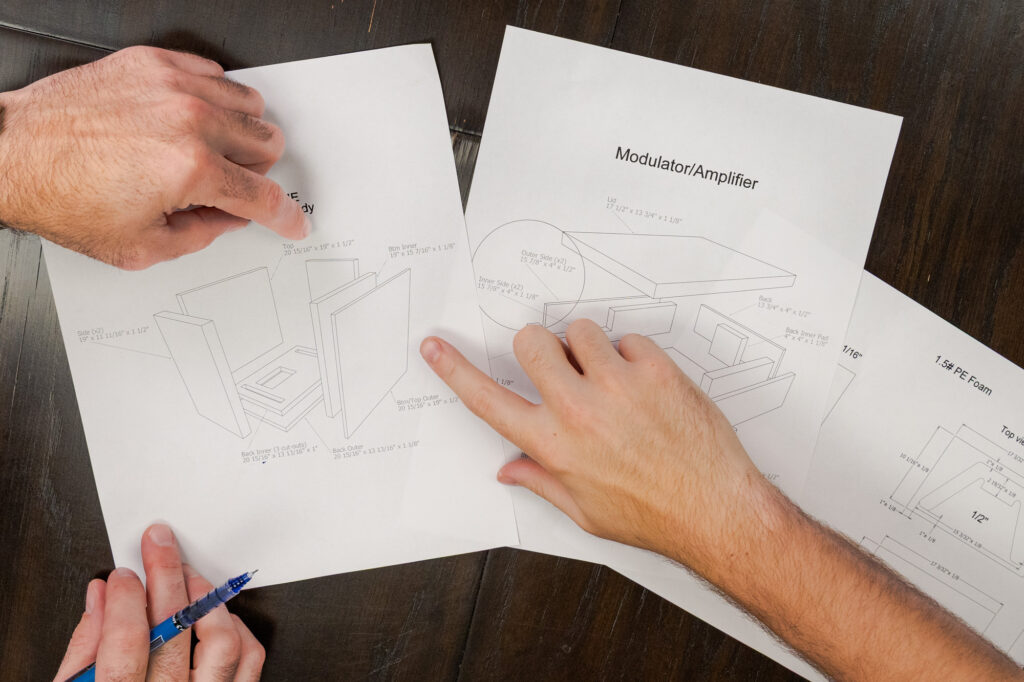

Our advanced equipment lets us cut, skive, and shape rubber to fit your exact measurements. Provide us with CAD files, drawings, or physical samples, and we make sure every piece is spot-on. Precise fabrication reduces waste, smooths the installation process, and produces components that fit just right.

Not Sure Yet? These FAQs Might Help

Absolutely. Whether you need a single prototype or thousands of parts for large-scale production, our facility is equipped to efficiently handle both. Small batches let you test designs and make adjustments, while high-volume runs ensure consistent quality. No matter your needs, every piece is fabricated to meet your specifications.

Yes! Using precision cutting and fabrication equipment, we can create rubber sheets, rubber rolls, and parts in virtually any thickness or width. Whether you need a thin gasket or a thick cushioning component, we can tailor dimensions to your exact requirements.

Definitely. Our team takes the time to review your project specs, considering factors like temperature range, environmental exposure, chemical contact, and mechanical stress. Then, we recommend the most suitable materials, so your parts last longer and perform reliably.