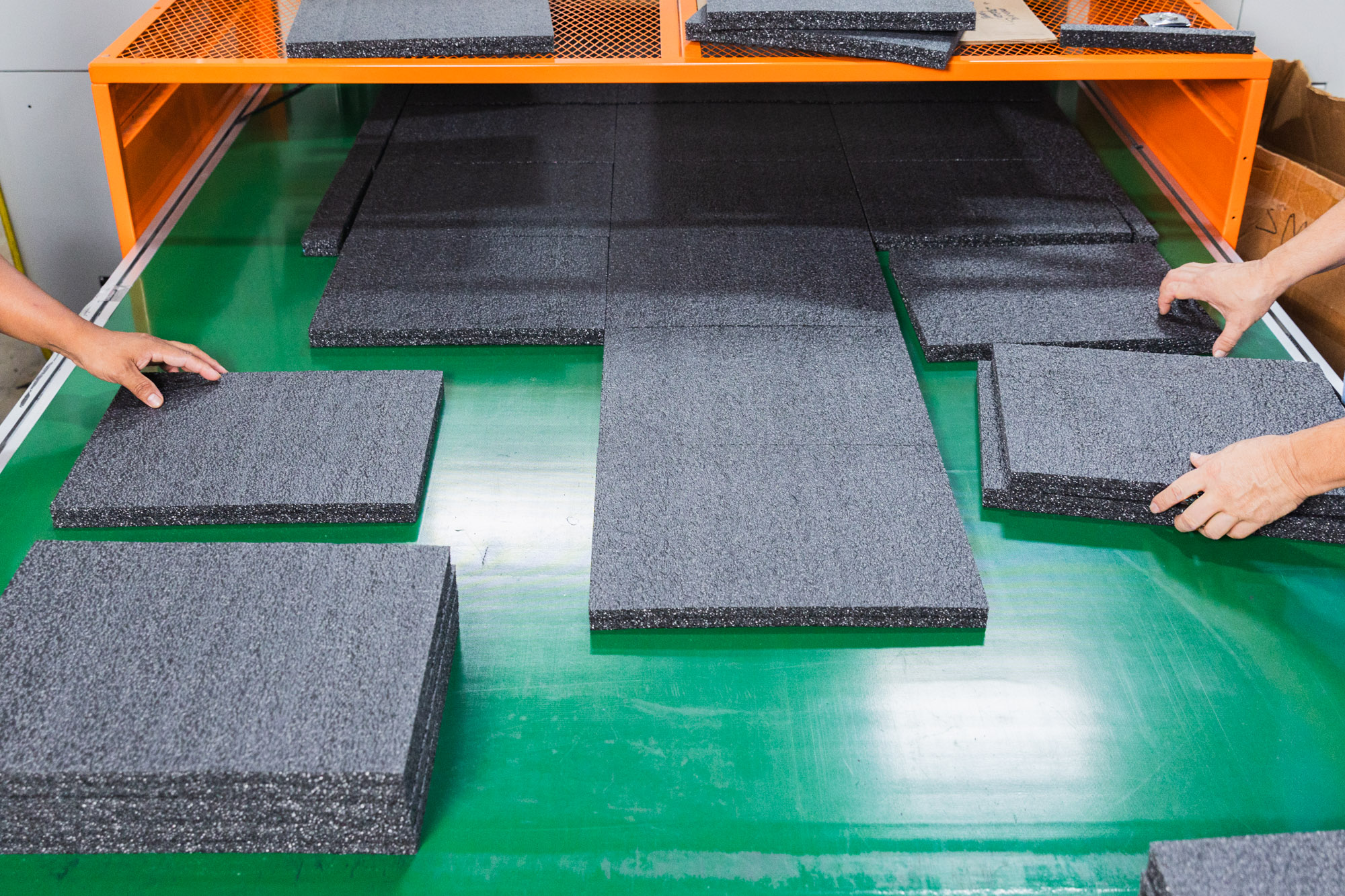

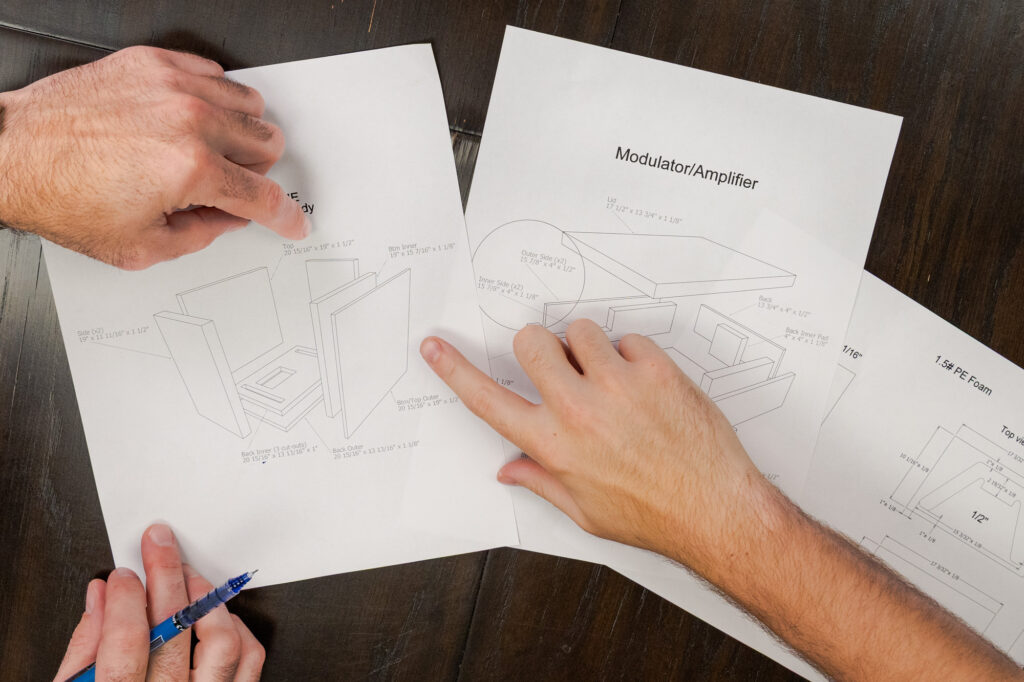

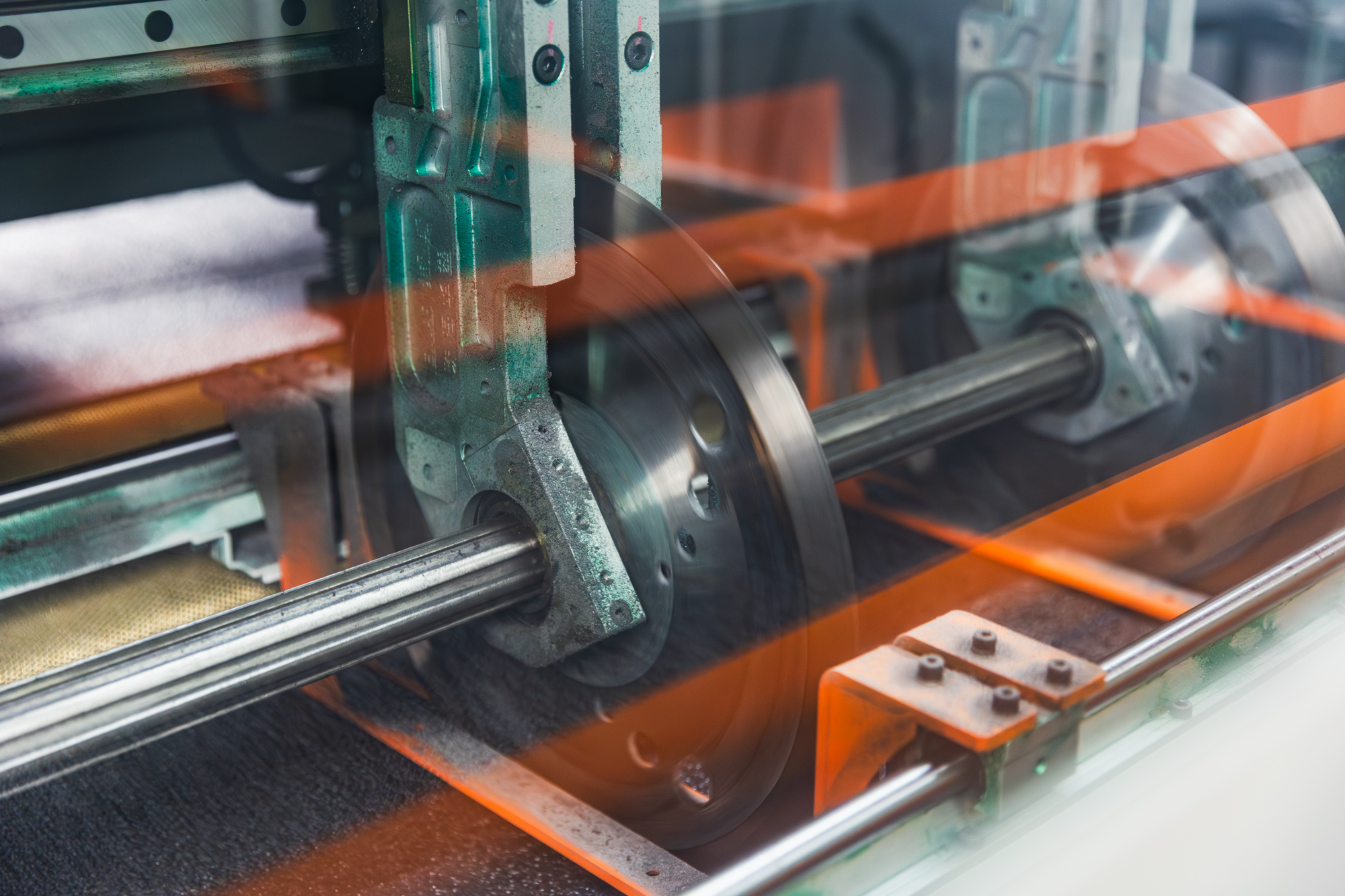

Absolutely. As a leading polyethylene foam supplier, we specialize in custom fabrication. Our capabilities include die cutting, laminating, routing, and shaping, so we can deliver foam pieces that meet your exact dimensions and performance requirements. Whether you need small prototypes or large-scale production, we at AM Foam Products can make it happen.

Lightweight Strength, Lasting Protection

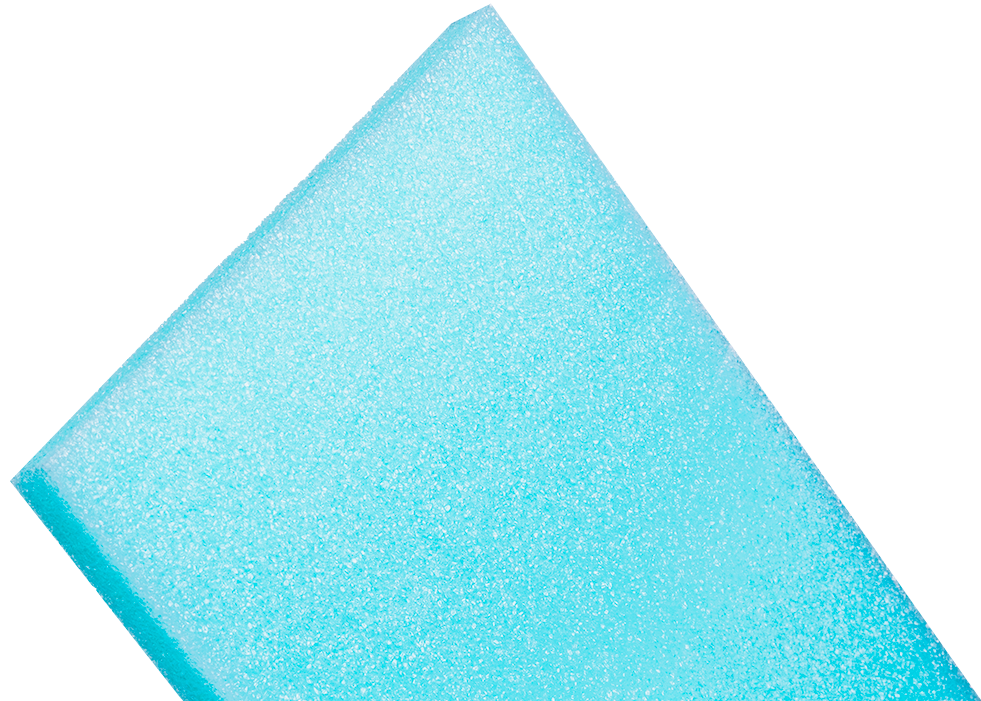

As a leading polyethylene foam supplier, AM Foam Products provides versatile foam products for various industries, like packaging and construction. Our high-performance polyethylene foam is lightweight, resilient, and fully customizable, making it the ideal solution for protection, cushioning, insulation, and specialty fabrications.

Solutions for Manufacturing, Shipping, and Beyond

We offer a wide range of polyethylene foam solutions, each designed to meet your specific needs.

Let’s Build Your

Custom Foam Solution

Check Out Our Process

A Deep Dive Into Polyethylene Foam

At AM Foam Products, we pride ourselves on delivering precisely engineered foam products that perform under pressure—literally. With our advanced equipment and commitment to quality, you’ll get polyethylene foam products that meet your exact specifications and timeline.

Not Sure Yet? These FAQs Might Help

Absolutely. We understand that material and fit testing are critical before committing to a large order. That’s why AM Foam Products offers samples and prototypes of our polyethylene foam products, so you can evaluate the material for your specific application. Testing allows you to confirm that the density, thickness, and durability are right before scaling production. Whether you’re exploring foam for protective packaging, thermal insulation, or industrial cushioning, our samples ensure you get the performance you expect with no surprises.

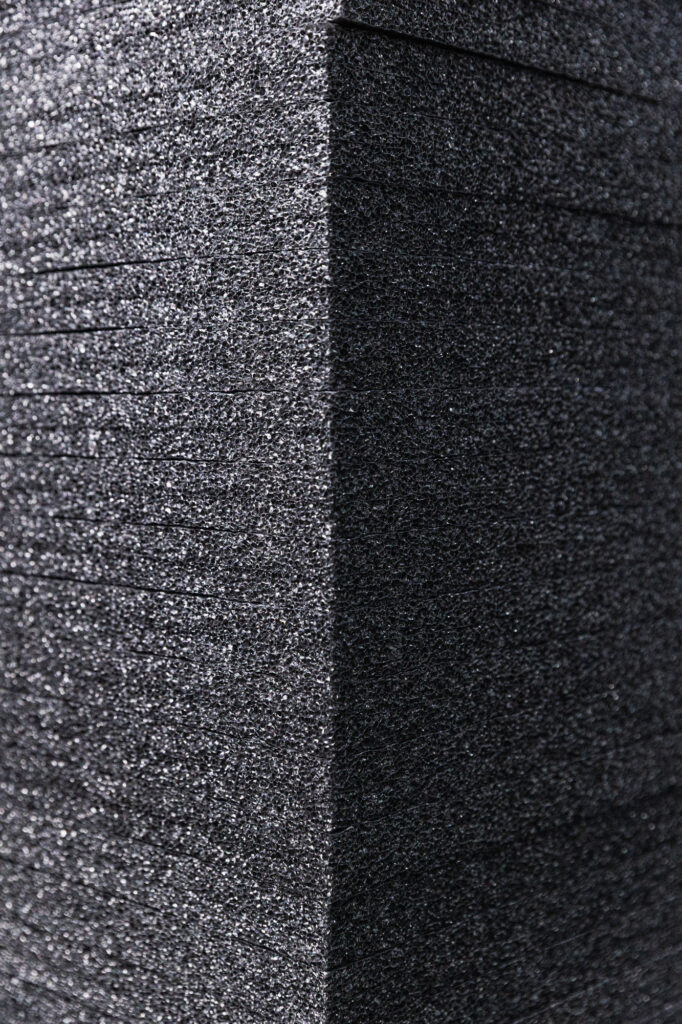

We supply polyethylene foam in low-density options designed for lightweight packaging and high-density foam engineered for insulation, structural integrity, and industrial use. Our team can help you select the best density for your specific application.

Yes. One of the biggest advantages of polyethylene foam is its closed-cell structure, which makes it naturally resistant to water, moisture, and many chemicals. This property makes it ideal for construction, marine, and healthcare applications where moisture protection is critical.

Definitely. As a trusted polyethylene foam supplier, AM Foam Products has the capacity to support both small-batch custom projects and high-volume production runs. We supply polyethylene foam in sheets, rolls, and custom die cut parts, with the ability to scale quickly and meet tight deadlines. Whether you need a handful of custom cut pieces for prototyping or truckloads of consistent sheet foam for large industrial applications, our advanced fabrication and logistics network maintains a commitment to quality, consistency, and on-time delivery, every time. Bulk pricing and expedited shipping are also available to support big or rush projects.

Yes. Polyethylene foam is a recyclable material, and AM Foam Products is committed to offering eco-conscious foam solutions. We work with clients to explore sustainable alternatives without compromising on performance.