Turnaround times for custom pattern cutting projects vary depending on the complexity of the design, material selection, and order size. Small, simple cuts can be completed within a few days, while larger or more intricate projects may take longer. At AM Foam Products, we pride ourselves on our efficient workflows and in-house production, which allows us to deliver high-quality results faster than many competitors. From the initial consultation to the final shipment, we provide clear timelines and updates, so you know exactly when to expect your order.

From Concept to Completion

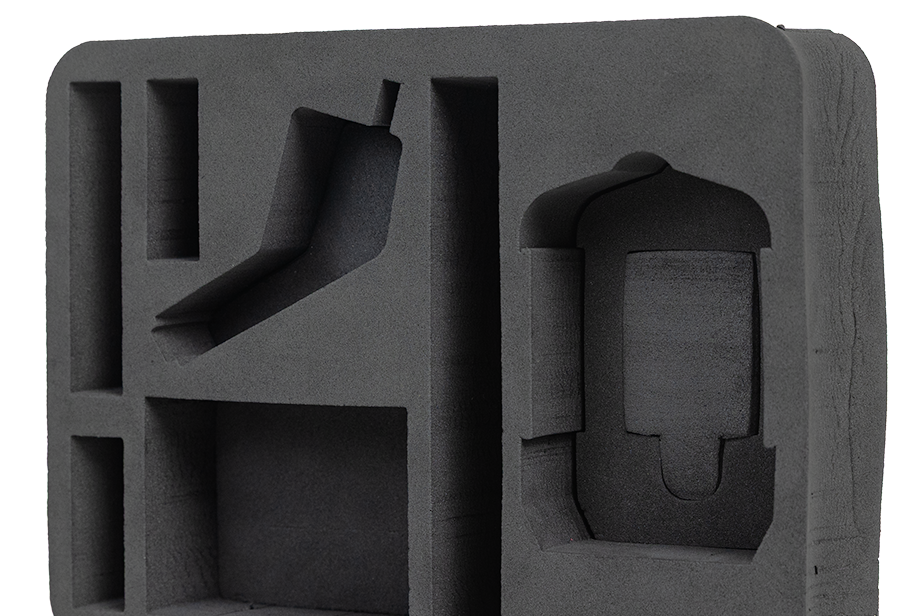

At AM Foam Products, we make pattern cutting simple. Our team specializes in transforming foam and rubber materials into precisely cut components that match your exact specs. Whether you need clean edges, intricate shapes, or tight tolerances, our skilled team and advanced cutting equipment can make it happen.

Your Design, Our Expertise

We provide pattern cutting services for diverse applications, from protective packaging to technical industrial components.

Let’s Build Your

Custom Cut Solution

Check Out Our Process

Custom Pattern Cuts for Any Shape You Can Imagine

AM Foam Products specializes in pattern cutting services that turn foam and rubber materials into precise components. No matter the project, our pattern cutting services save you time, reduce errors, and create the custom foam and rubber solutions your business needs. From simple geometric shapes to complex, intricate designs, our team can produce parts that fit your specifications with unmatched accuracy.

Not Sure Yet? These FAQs Might Help

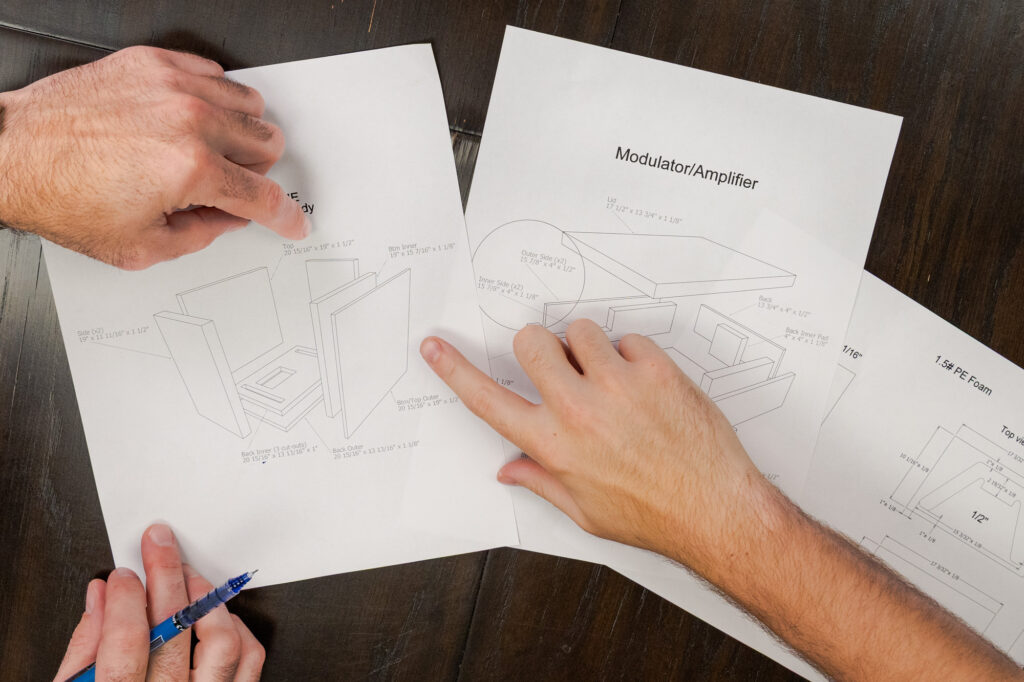

Absolutely. Our team can work directly from CAD files, technical drawings, or physical prototypes, precisely cutting your foam parts to fit your specifications. By leveraging digital files, we can maintain exact tolerances, replicate complex geometries, and minimize errors during production. This ensures that every piece, whether it’s for packaging, gaskets, specialty industrial components, or anything else, meets your functional and dimensional requirements.

Yes. Prototyping is a critical step in our process. We can produce sample parts or small test runs so you can evaluate the fit, function, and durability of your design before committing to large-scale production. This allows you to make adjustments early and analyze material performance, so that the final product meets your expectations. In the long run, prototyping reduces waste, improves efficiency, and gives you confidence in your finished product.

Definitely. AM Foam Products is fully equipped to handle small-batch and high-volume orders. Our experienced team and advanced in-house equipment maintain quality across every cut, regardless of quantity. Whether you need a few custom pieces or thousands of identical parts, we can scale production to meet your timeline and budget while maintaining strict tolerance and performance standards.

We can pattern cut a wide selection of materials, including polyurethane foam, polyethylene foam, roll rubber, and specialty foams. Our team can help you select the best material for your specific application, whether it’s protective packaging, gaskets, cushioning, or industrial components. Each material has unique properties, such as shock absorption, durability, moisture resistance, or chemical resistance, allowing us to create custom solutions for your exact needs.