Absolutely. AM Foam Products is fully equipped to manage both small-batch projects and large-scale, high-volume production runs. Our advanced, in-house machinery and streamlined workflows maintain consistent quality, precise dimensions, and reliable adhesion across every lamination, regardless of order size. By keeping production under one roof, we reduce lead times and maintain tight control over schedules, enabling us to meet even the most demanding deadlines without compromising on quality craftsmanship or performance.

Innovative Layering for Better Performance

AM Foam Products provides professional foam laminating services that bring multiple layers or different materials together into a single, high-performance assembly. Whether you need foam for protective packaging or specialty applications, our team verifies that every lamination meets your exact specifications. We focus on precise adhesion, uniform thickness, and long-lasting durability, so your laminated foam performs consistently in real-world conditions.

Durable Assemblies Tailored to Your Industry

From single-layer bonding to complex, multi-material assemblies, AM Foam Products’ custom foam laminating services are tailored to your specs.

Let’s Build Your

Custom Foam Solution

Check Out Our Process

Custom Foam Laminates for Every Application

Our laminating process includes assembling multiple layers or types of foam into a single, durable unit to ensure precise thickness, consistent adhesion, and optimal performance for your project. Whether you need a single-layer bond or a complex, multi-material structure, AM Foam Products delivers laminated foam solutions that are both functional and reliable.

Not Sure Yet? These FAQs Might Help

We work with a broad range of foam materials, including polyurethane, polyethylene, rubber, and specialty foams. Our laminating process can combine multiple layers or different materials to create products with custom performance characteristics. This makes foam assemblies effective for applications that require specific cushioning, thermal insulation, vibration dampening, or packaging protection. Our team evaluates your project requirements to recommend the optimal materials, ensuring that your laminated foam assembly meets your standards for function and durability.

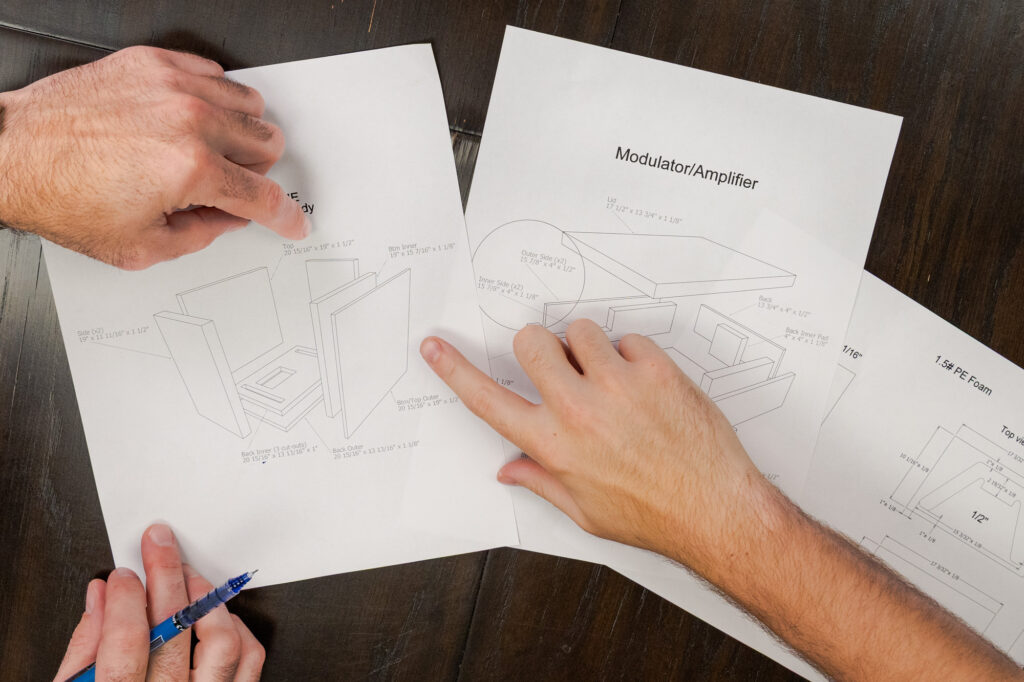

Yes. We strongly recommend prototyping to validate your design before committing to full-scale production. Prototypes allow you to test the fit, adhesion strength, density, and overall functionality of the laminated foam assembly in real-world conditions. This process minimizes risk, helps you identify and adjust potential issues early, and ensures that the final production meets all performance and dimensional specifications. Once a prototype is approved, we can scale production confidently and efficiently.

Absolutely. AM Foam Products’ die cutting and precision laminating capabilities allow us to produce foam layers in virtually any shape, size, or thickness. Whether you need simple, geometric cuts, complex, contoured shapes, or multi-layered assemblies, we can achieve precise tolerances to meet your project’s specifications. Our in-house fabrication promotes flexibility, accuracy, and quick turnaround times for both standard and custom orders.