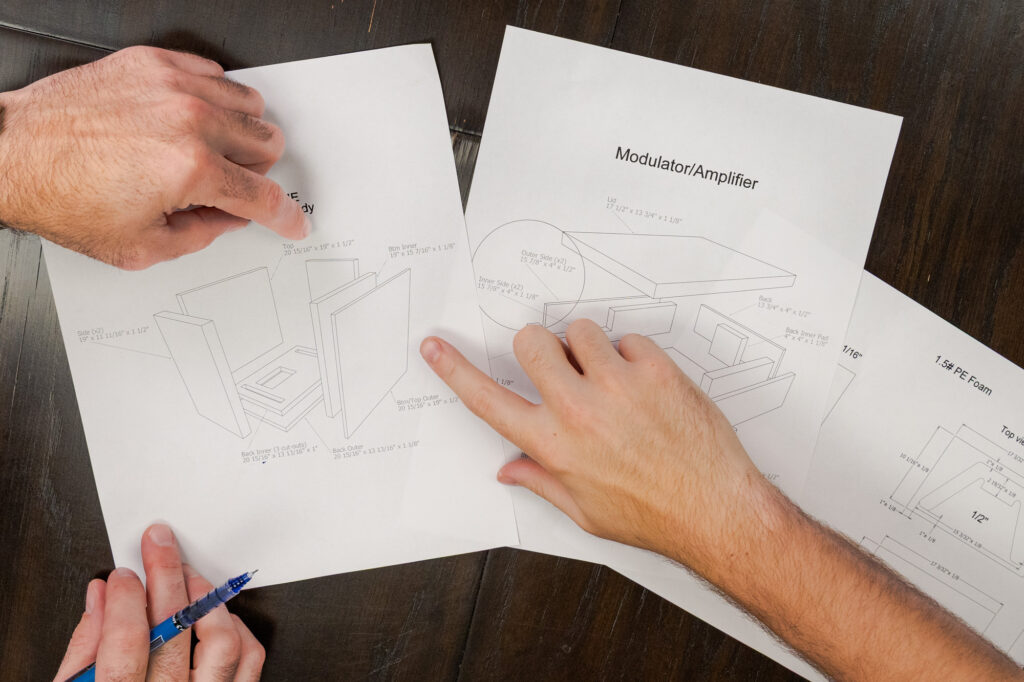

Yes. Our prototyping services are perfect for any automotive manufacturer or supplier’s needs. We can produce precisely engineered gasket prototypes to test fit, sealing performance, durability, and functionality before committing to a large-scale production. This allows design teams to identify and resolve potential issues early, reducing risk, cost, and time-to-market.

Precise Cuts for a Reliable Fit

As leading automotive gasket manufacturers, AM Foam Products supports the transportation and mobility industry with durable, precision cut foam products. From vehicles to specialty equipment, we engineer components that enhance performance, comfort, and reliability for long-term applications.

Scalable Solutions for the Transportation Industry

We provide high-performance foam and gasket solutions designed to meet strict automotive and transportation standards, ensuring safety, efficiency, and long-lasting durability.

Let’s Build Your

Custom Foam Solution

Check Out Our Process

High-Performance Automotive Seals

At AM Foam Products, we understand the critical role gaskets and foam components play in vehicle performance and passenger safety. As experienced automotive gasket manufacturers, we deliver solutions that stand up to heat, vibration, pressure, and environmental challenges.

Not Sure Yet? These FAQs Might Help

Absolutely. As one of the leading automotive gasket manufacturers, AM Foam Products’ state-of-the-art manufacturing facility and skilled production team are equipped to manage high-volume orders for OEMs and Tier 1 suppliers worldwide. Our processes maintain consistent quality, tight tolerances, and reliable delivery, making us a trusted partner for companies with demanding supply chain requirements. All gaskets undergo rigorous quality control, material testing, and performance validation to meet or exceed automotive industry standards, providing reliability and confidence for manufacturers.

We work with a variety of rubber compounds, polyurethane, polyethylene, and specialty foams to meet the performance, chemical resistance, and temperature requirements of automotive applications. Our engineers collaborate with your design team to select materials, refine dimensions, and optimize gasket geometry to improve sealing, vibration dampening, and long-term durability.