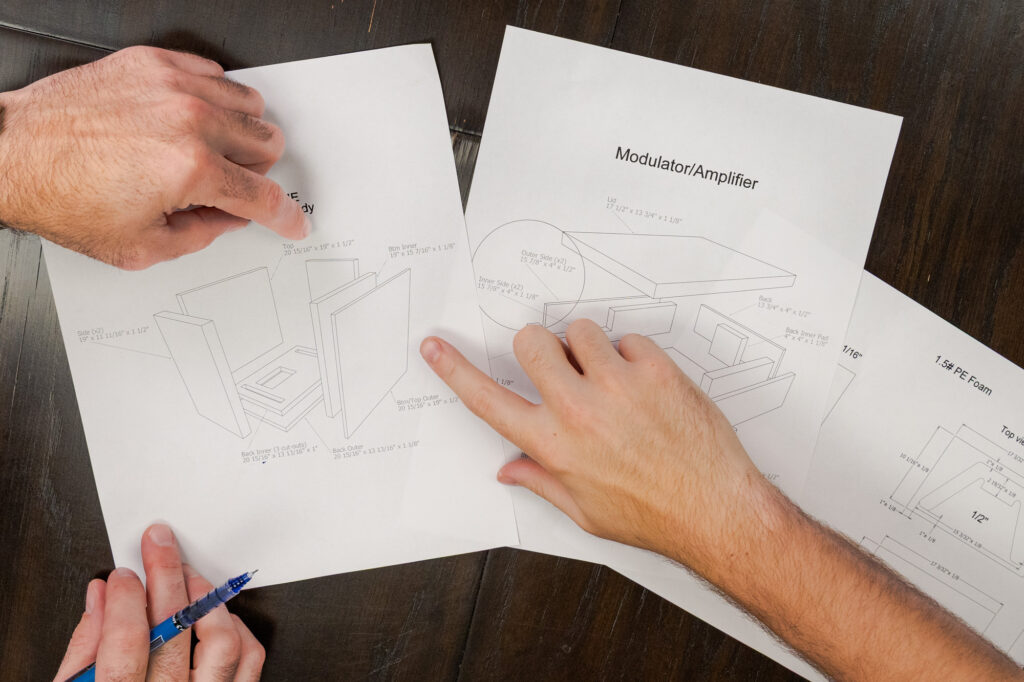

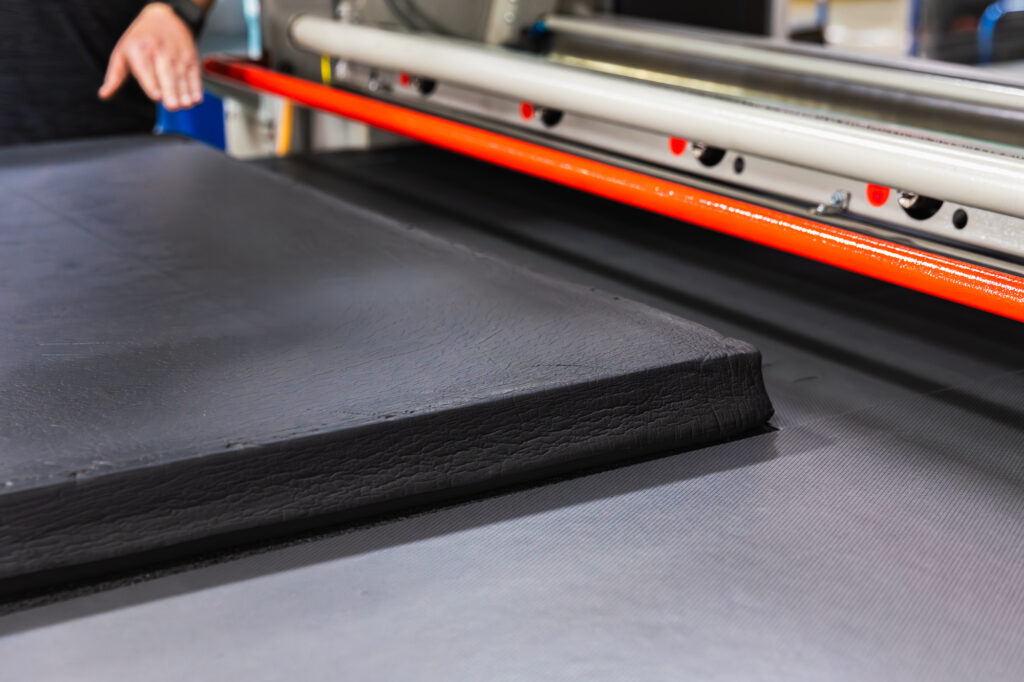

Yes. We use precision die cutting to produce XLPE foam in custom shapes, sizes, and thicknesses. We can work from CAD files, technical drawings, or physical samples to create a final product that meets your exact specifications.

Built Tough for Demanding Applications

Cross-linked polyethylene foam (XLPE) is a closed-cell material known for its durability, moisture resistance, and shock absorption. At AM Foam Products, we supply and fabricate XLPE to meet the exact specifications of industries like medical, automotive, and even industrial packaging.

Sheets and Custom Parts

Whether you need sheets or custom die cut parts, AM Foam Products delivers precision-engineered XLPE products in various densities, colors, and thicknesses.

Let’s Build Your

Custom Foam Solution

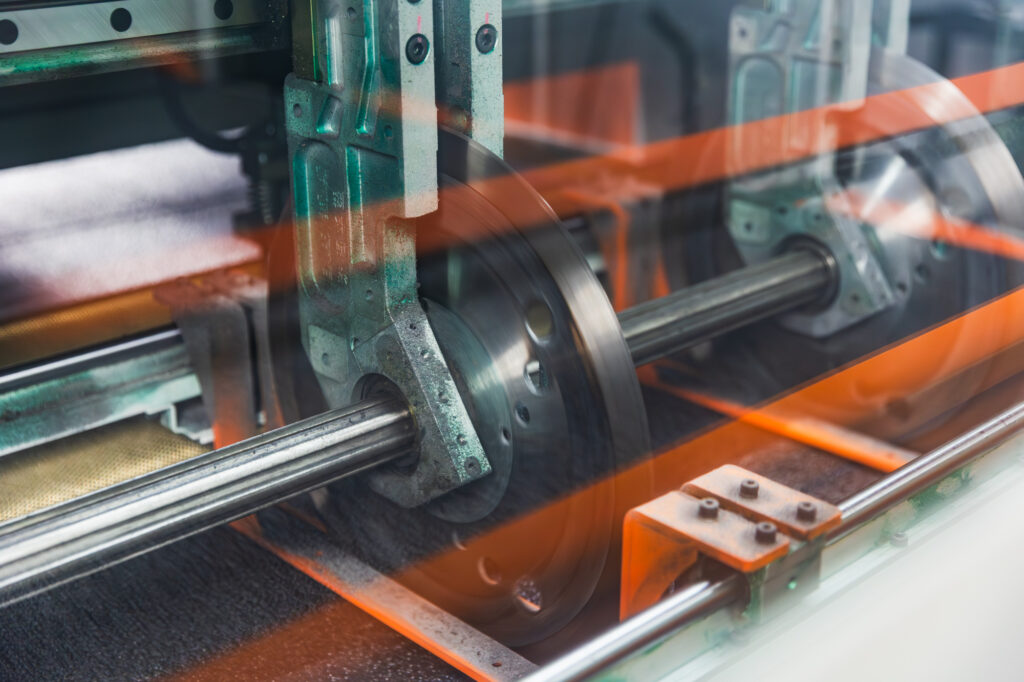

Check Out Our Process

A Deep Dive Into XLPE Foam

Cross-linked polyethylene foam, often referred to as XLPE, is a versatile, closed-cell material known for its strength, durability, and flexibility. At AM Foam Products, we specialize in fabricating custom XLPE products. Whether you need foam sheets, roll rubber, or precision-cut components, our team ensures that every product is engineered for performance.

Not Sure Yet? These FAQs Might Help

Yes. We supply XLPE foam in multiple densities, from soft cushioning foams to high-density structural foams. Additionally, we have a variety of colors to match branding, product design, or industry standards.

We understand that every project is unique, which is why AM Foam Products offers multiple densities, colors, and thicknesses to match your specific needs. Our in-house team can assist you in selecting the right grade of foam for your application, ensuring optimal, cost-effective performance.

Absolutely. One of the key benefits of XLPE foam is its closed-cell structure, which makes it naturally resistant to water absorption, mold, mildew, and many common chemicals. This makes it perfect for outdoor applications, marine use, and humid environments.

Yes. Certain grades of cross-linked polyethylene foam meet FDA and medical standards for direct or indirect contact. This makes it a reliable choice for medical devices, orthotics, food packaging, and anywhere that safety and hygiene are critical.

XLPE foam is known for its long service life. It resists compression set, UV exposure, and physical wear, maintaining its shape and performance even in demanding environments. This makes it ideal for long-term industrial, automotive, and construction applications.