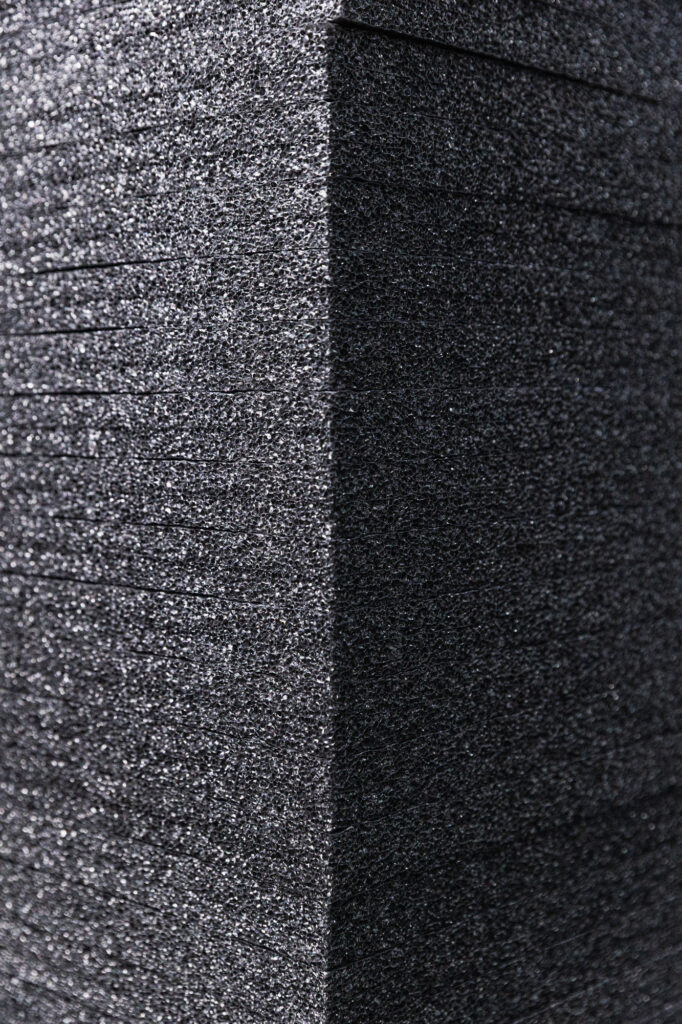

We can skive foam to precise thicknesses, working with thin sheets, a fraction of an inch, and thick sheets, up to 5 inches, depending on the foam type and intended application. Our advanced skiving machines allow us to maintain a uniform thickness across each sheet or roll, creating repeatable results for critical applications. Whether you need ultra-thin cushioning layers for electronics, mid-density insulation panels, or thick foam components for industrial machinery, we can deliver tight tolerances with smooth, consistent finishes.

Custom Foam Cutting Services for Exact Fit & Function

At AM Foam Products, we provide expert foam skiving services to achieve precise thicknesses and profiles for any project. From protective packaging to specialty industrial components, our skilled team maintains consistency and quality across projects, tailored to your specifications.

Reliable, Repeatable Foam Fabrication

AM Foam Products combines advanced equipment and expert craftsmanship to provide custom foam cutting services that deliver precise tolerances, repeatable performance, and efficient production for any project.

Let’s Build Your

Custom Foam Solution

Check Out Our Process

Advanced Skiving Capabilities

Our custom foam cutting services create precise, uniform thicknesses across sheets, rolls, or custom shapes. Whether you need protective packaging, cushioning, sound-dampening layers, or specialty industrial components, our expert team produces each piece to meet your exact specifications.

Not Sure Yet? These FAQs Might Help

Absolutely. AM Foam Products is fully equipped to handle both small-batch projects and high-volume production runs. Our facility’s skilled technicians use state-of-the-art skiving equipment to maintain consistent quality across every piece, even in large orders. From a few prototypes to thousands of skived sheets or rolls, we prioritize reliable delivery, precise tolerances, and superior finishes, making us a trusted partner for manufacturers and OEMs requiring scalable foam solutions.

We can skive a wide variety of foam materials, including polyurethane, polyethylene, rubber, and specialty foams. Each material has unique properties, and our team works with you to select the best option for your application—whether it’s protective packaging, cushioning for delicate electronics, industrial gaskets, or specialized automotive and aerospace components. Our expertise ensures that the skived foam meets performance, durability, and safety requirements while achieving the precise thickness and consistency your project demands.

Of course! At AM Foam Products, our foam skiving services can be seamlessly integrated with additional fabrication processes, such as die cutting, laminating, or adding pressure-sensitive adhesive (PSA) backing. This means we can deliver finished foam assemblies that are ready for immediate use, saving you time and simplifying your production workflow. By combining and performing these processes in-house, we maintain precise dimensions, uniform thickness, and consistent quality across every piece. Whether you need multi-layered cushioning, custom gaskets, or laminated assemblies for industrial, medical, or automotive applications, our integrated approach ensures components meet your exact specifications while maximizing efficiency and reliability.

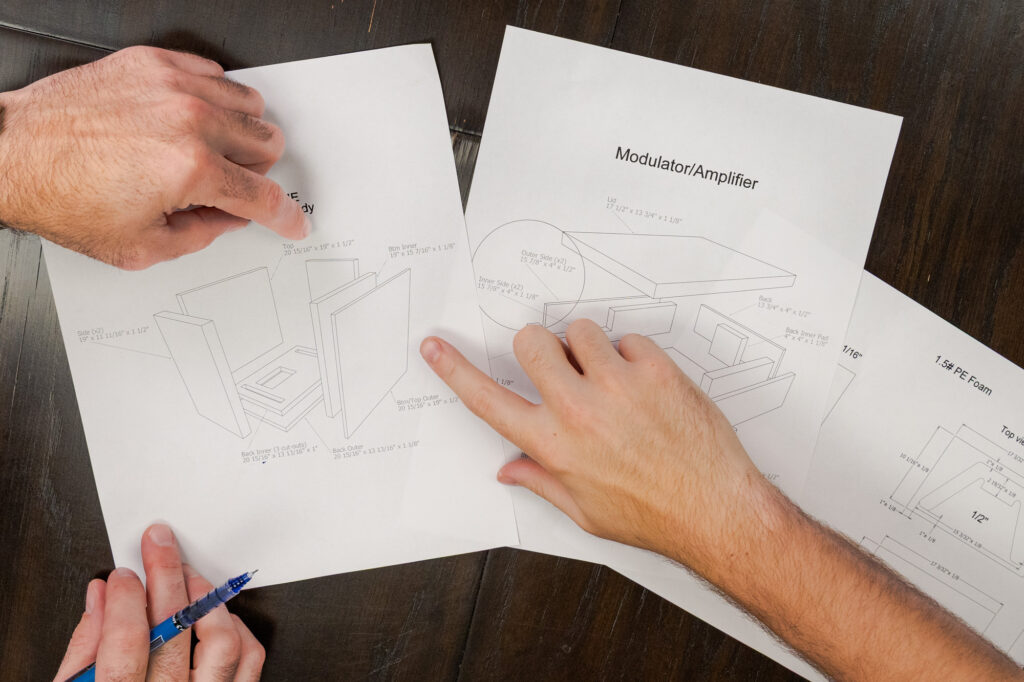

Absolutely. We offer prototyping services so you can test fit, thickness, and functionality before committing to a large-scale production run. This helps us identify and adjust potential design flaws early, reduces risk, and ensures the final product meets your exact requirements.

Yes. Our advanced skiving equipment allows us to produce foam and foam inserts in virtually any shape. Whether your project requires uniform sheets, tapered layers, or intricate cutouts, we can achieve precise, repeatable results for specialized applications.