We work with a wide range of materials, including polyethylene, polyurethane, cross-linked foam, rubber foam, and specialty engineered foams. Each material offers unique benefits, such as cushioning, thermal insulation, or chemical resistance, allowing us to match the right foam to your project’s performance requirements.

Engineered Foam Solutions Across Industries

At AM Foam Products, we provide custom foam fabrication services tailored to your exact specifications. From protective packaging and insulation to automotive parts and specialty applications, our expert team uses state-of-the-art equipment to deliver durable, cost-effective foam solutions, no matter the industry.

Scalable Fabrication for Any Project

From initial design to large-scale production, AM Foam Products delivers custom solutions that meet performance, budget, and timeline requirements.

Let’s Build Your

Custom Foam Solution

Check Out Our Process

Industry Leading Foam Fabrication

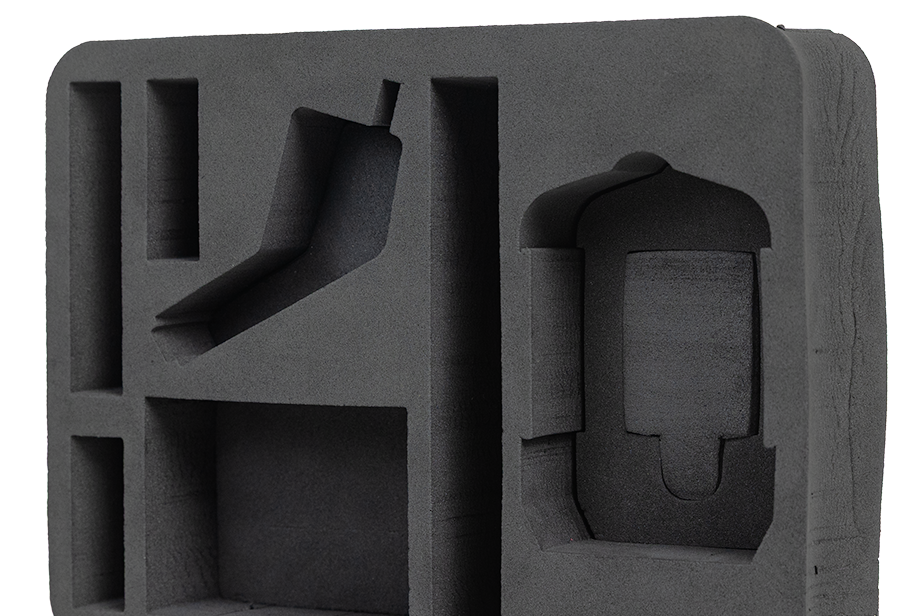

From packaging inserts and gaskets to thermal insulation and cushioning systems, our team can design and manufacture precise foam components that deliver the performance, protection, and durability you need.

Not Sure Yet? These FAQs Might Help

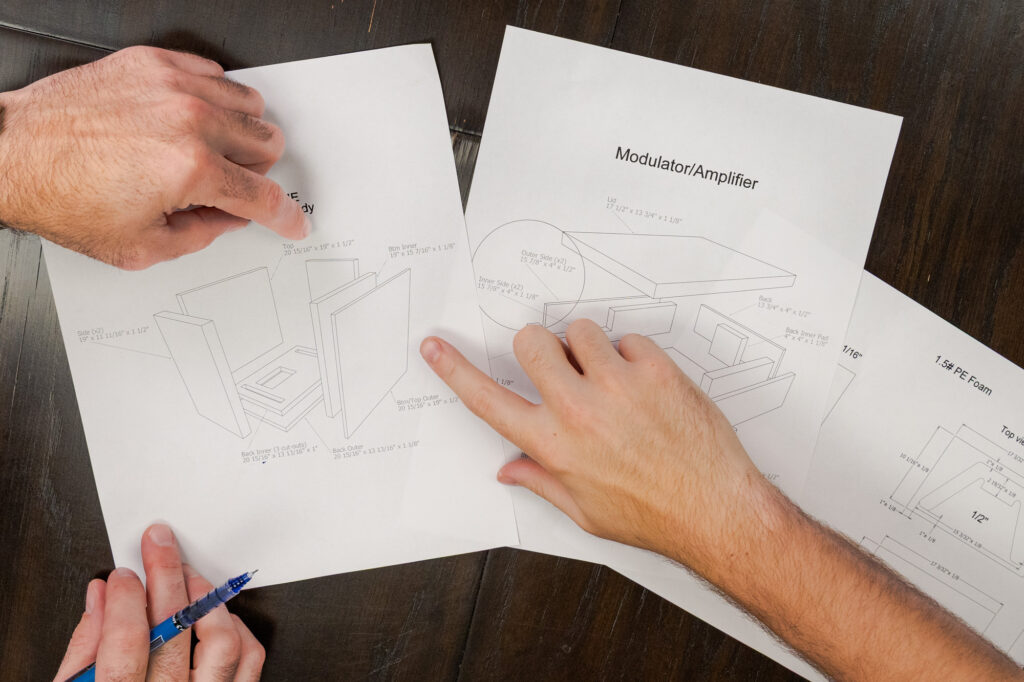

Yes. We provide detailed prototyping and sampling services so you can test your design before scaling up to a full production run. This includes verifying dimensions, density, and durability, so you can be confident that the foam will perform as intended in real-world conditions.

Absolutely. We can fabricate foam pieces into nearly any size, thickness, or shape. Whether you need precise gaskets, inserts, or complex geometries, we deliver customizable results.

Yes. At AM Foam Products, we have the production capacity to handle everything from one-off custom jobs to large-scale, ongoing supply contracts. Our streamlined processes support efficiency and consistent quality, whether you need a few components or thousands of units.

Our custom foam fabrication services are trusted across multiple industries, including packaging, automotive, aerospace, marine, healthcare, electronics, and industrial manufacturing. From protective case inserts to specialty seals and medical-grade components, we can adapt to meet diverse industry standards.

Yes. Our team works closely with clients to refine designs and material selections. We can collaborate on drawings, prototypes, and production plans to optimize performance and cost-efficiency.

Whenever possible, we recommend recyclable and sustainable foam materials for environmentally conscious projects. We also help clients reduce waste by using efficient cutting techniques and making smart material selections. We have 100% recyclable material available.