We supply a wide variety of high-performance foam materials to meet the unique demands of industrial environments. Our selection includes polyurethane for excellent cushioning and flexibility, polyethylene for lightweight durability and moisture resistance, and rubber, known for superior sealing and vibration dampening. We also provide specialty foams engineered for extreme conditions, such as chemical exposure, temperature fluctuations, or heavy mechanical stress. Each material is chosen for its durability, performance, and compatibility with your specific application.

Scalable Solutions for Performance & Protection

AM Foam Products delivers industrial foam products engineered for reliability, durability, and precision. From protective packaging to equipment padding, our foam solutions support manufacturing processes across a diverse range of industries.

Foam Fabrication Services for Industrial Projects

Our advanced foam fabrication services provide custom cut components for demanding industrial environments, ensuring reliable performance, thorough protection, and scalability for projects of any size.

Let’s Build Your

Custom Foam Solution

Check Out Our Process

Durable, Custom Solutions for Manufacturing & Production

At AM Foam Products, our industrial foam capabilities provide the strength, precision, and versatility manufacturers need to keep production running smoothly. Whether you need protective packaging for shipping or insulation for noise and vibration control, we engineer foam products that stand up to the demands of industrial environments.

Not Sure Yet? These FAQs Might Help

Absolutely. AM Foam Products’ state-of-the-art manufacturing facility is designed to manage projects of any size—from initial small-batch prototypes to large-scale production runs for ongoing industrial supply. Our advanced machinery, skilled technicians, and streamlined processes maintain consistent quality, fast turnaround times, and reliable delivery schedules. Whether you’re a small manufacturer or a global operation, our scalable production capabilities adapt seamlessly to meet your timeline and volume requirements without sacrificing performance or precision.

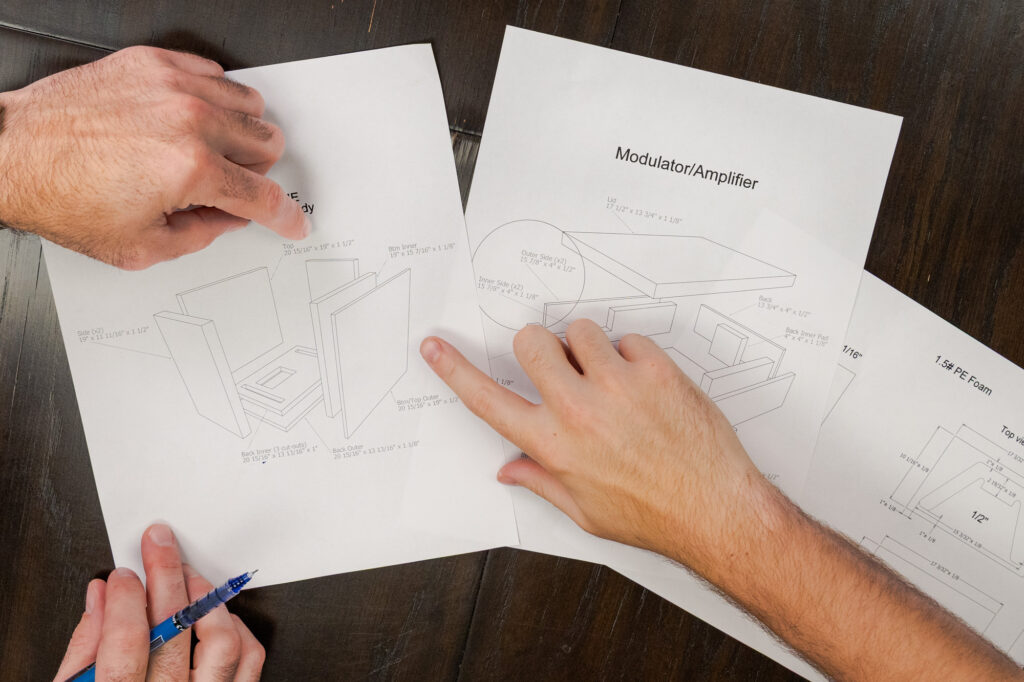

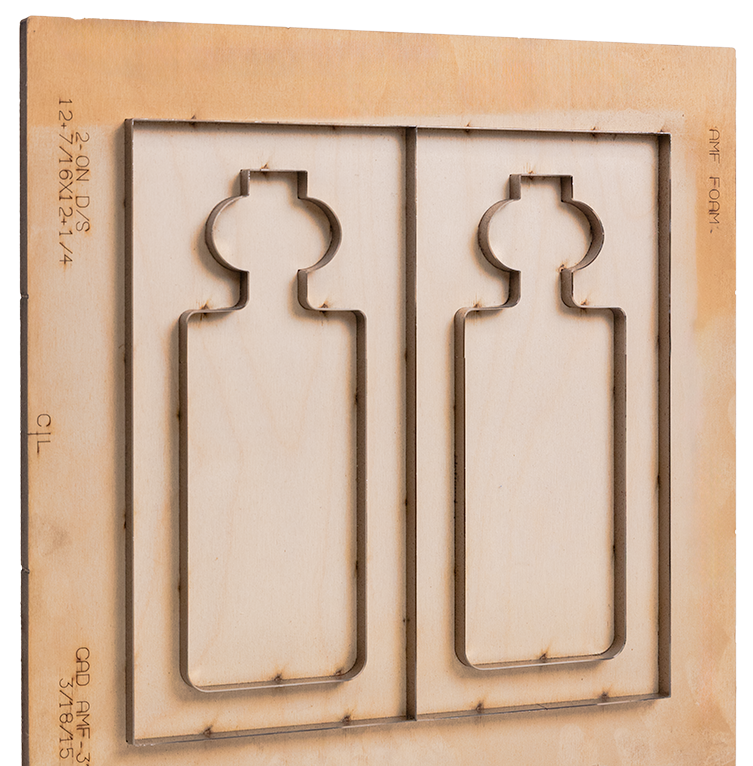

Yes. Our team specializes in custom foam fabricated to your exact specifications. By working from your CAD files, detailed drawings, or product requirements, we can produce precision cut foam components that integrate perfectly into your manufacturing or assembly process. Using advanced techniques, like skiving and die cutting, we create parts that match complex geometries, tight tolerances, and unique performance needs. Whether it’s protective inserts, seals, or vibration dampeners, our custom solutions improve efficiency and add value to your industrial applications.