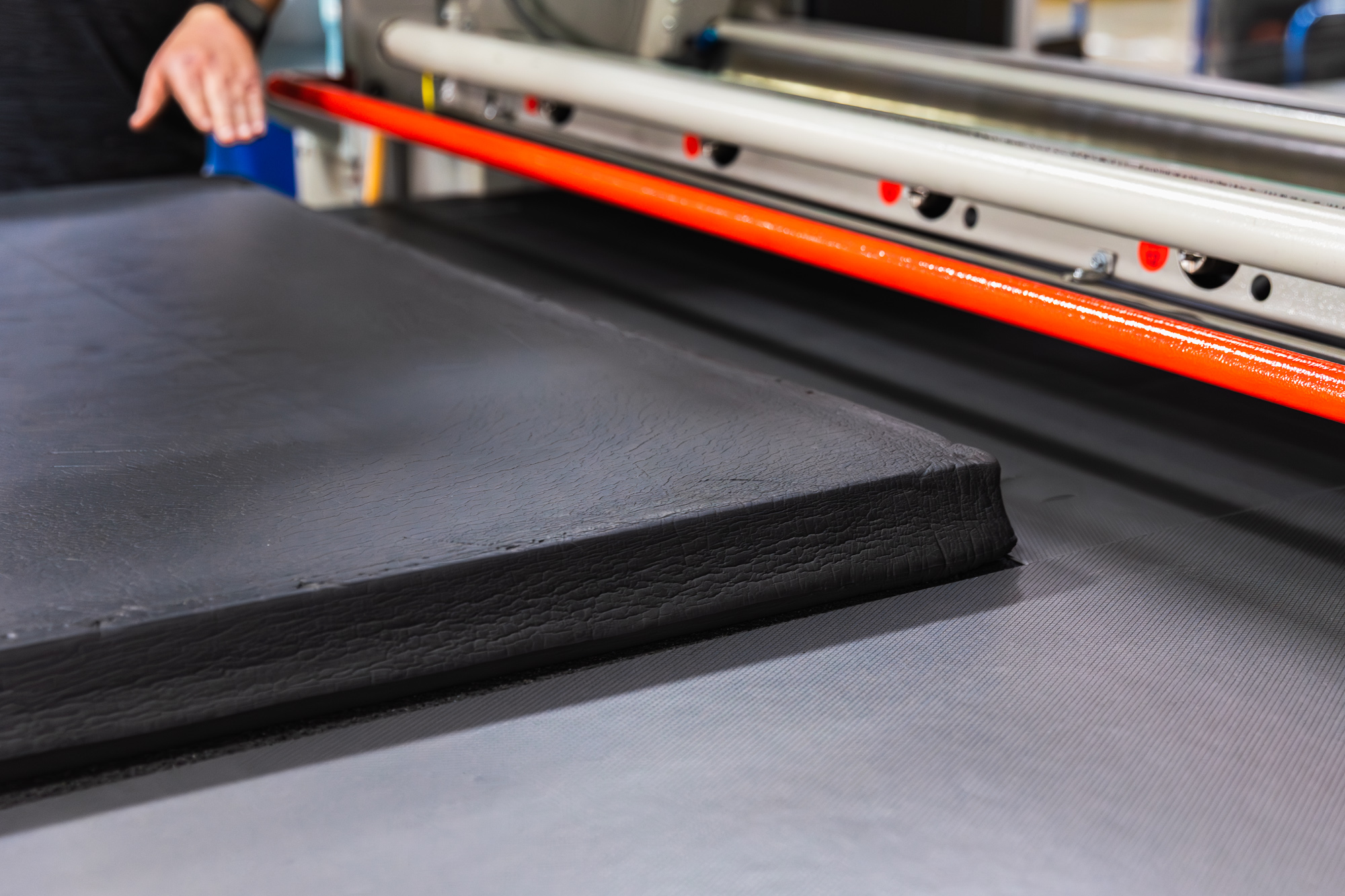

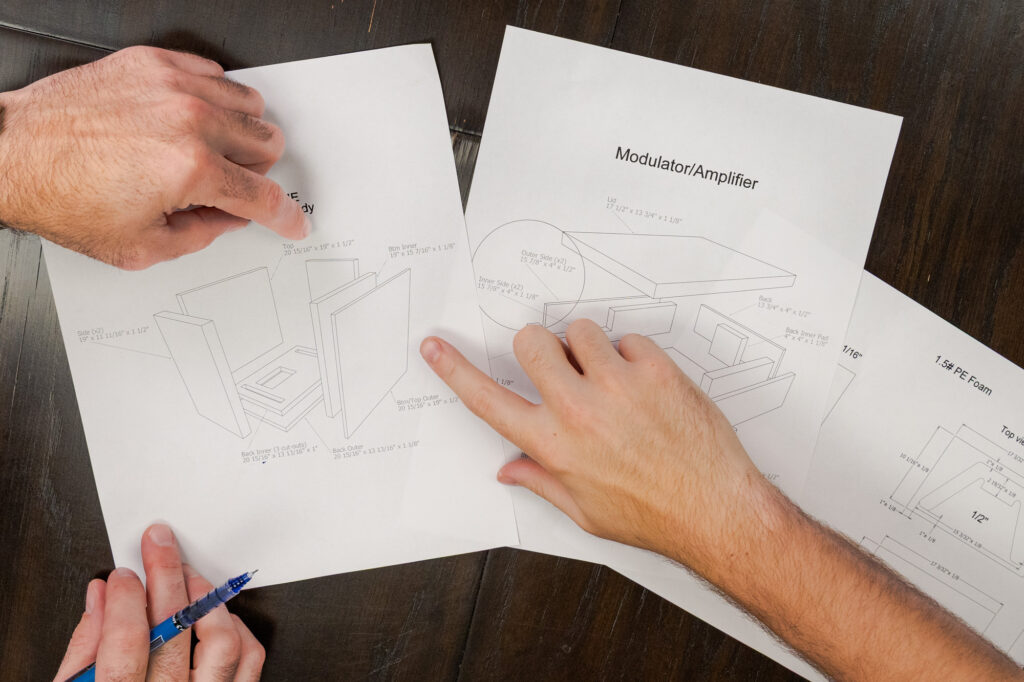

Yes. At AM Foam Products, we use advanced precision cutting equipment to deliver rubber sheets that match your exact specifications. Whether you provide detailed CAD files, hand-drawn designs, or basic measurements, our team confirms that every cut is accurate and consistent. This level of customization makes it easy to integrate our rubber sheets into your product, packaging, or industrial process without additional trimming or modification.

Sheets and Products Tailored to Your Specs

At AM Foam Products, we supply premium rubber sheets tailored to your specifications. Whether you need chemical-resistant, heat-tolerant, or weatherproof materials, our team delivers precision cut solutions to meet your exact application.

Designed for Longevity

We carry a wide range of rubber sheet materials, available in different thicknesses, hardness levels, and finishes, for a variety of industries.

Let’s Build Your

Custom Rubber Solution

Check Out Our Process

Rubber Sheets You Can Rely On

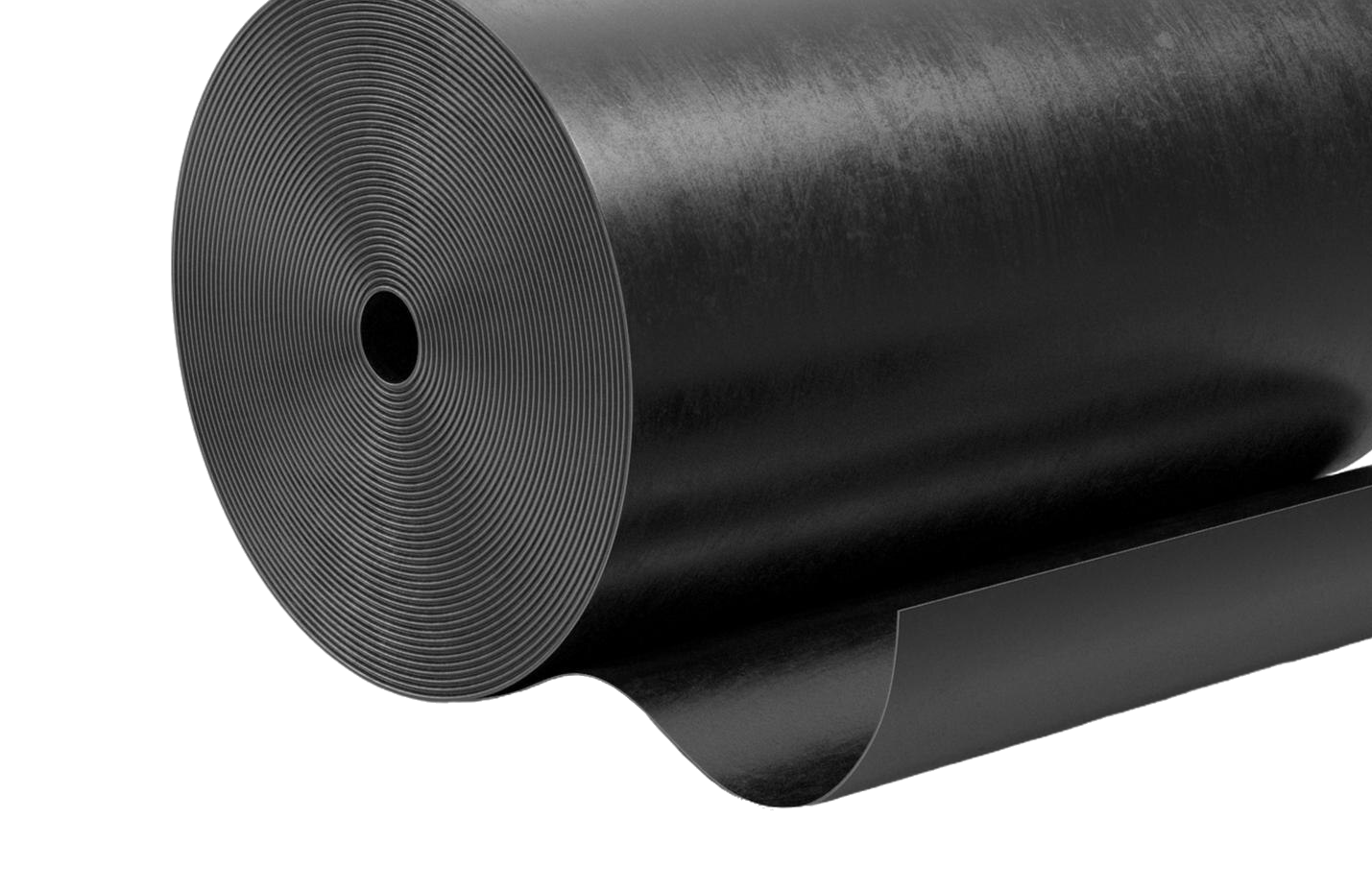

We at AM Foam Products are a trusted sponge rubber sheet supplier that delivers high-quality materials to meet the needs of industrial, commercial, and specialty applications. From cushioning and sealing to vibration dampening and insulation, our rubber foam products are engineered for performance, durability, and precision. Whether you need sheets, rolls, or custom-cut components, we provide solutions that fit your exact requirements.

Not Sure Yet? These FAQs Might Help

Absolutely. We carry an extensive selection of rubber sheet options for a wide range of applications. Our inventory includes multiple thicknesses and durometer (hardness) levels, giving you flexibility in choosing the right balance of durability, flexibility, and cushioning for your project. Whether you need thin, flexible rubber for gasketing or thicker, denser sheets for heavy-duty industrial use, we can supply the right material.

Yes. While AM Foam Products is fully equipped for high-volume production, we also support customers who need small runs or prototype samples. Prototyping allows you to test the fit and performance of your rubber sheets before committing to a full-scale production run. This approach saves time, minimizes risk, and ensures you get exactly what you need for your final application.